Charging LFP (LiFePO4) batteries to 90% SOC, or not

karrak

Solar Expert Posts: 326 ✭✭✭✭

Before I installed an LFP battery in my off grid power system in 2013 I researched the best charge parameters for safety and most cost effective utilisation of the battery. I came to the conclusion that charging to only 90%SOC was a good idea. After four years of use, more research and some experimentation I no longer think this is the case both from a practical point of view and with regards to battery utilisation.

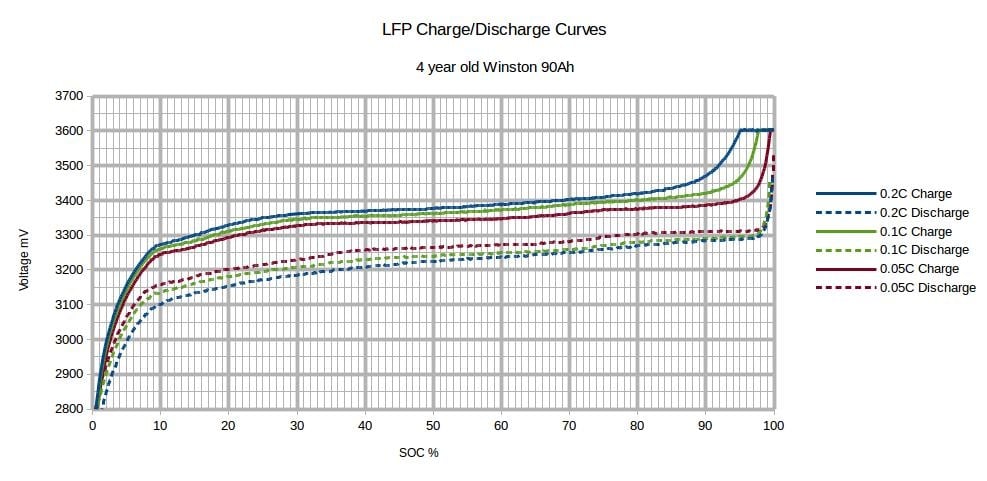

Charging to 90% if you have a power supply that has a fixed current output is reasonably easy to do. With reference to the graph below for Winston cells all one has to do is charge at a fixed rate of 0.25C and terminate the charge when the voltage reaches 3.45V/cell (13.8V for a twelve volt battery).

The big problem is that if you are charging from solar the charge rate is not constant. In my case it can go from a maximum of ~0.12C to 0.0C. If you look at the graph this equates to an SOC of anything from ~98% to ~99%+ if charging at 3.45V/cell. If I pick a lower charge voltage of 3.4V/cell (13.6V for 12V battery) I can get a final SOC from ~85% to~96%+ with the controller going into the absorb phase and limiting the rate that the battery is charged at ~85% SOC. If I were charging at a rate of 0.2C this would be ~70%, not much good in the middle of winter!

Simon

Charging to 90% if you have a power supply that has a fixed current output is reasonably easy to do. With reference to the graph below for Winston cells all one has to do is charge at a fixed rate of 0.25C and terminate the charge when the voltage reaches 3.45V/cell (13.8V for a twelve volt battery).

The big problem is that if you are charging from solar the charge rate is not constant. In my case it can go from a maximum of ~0.12C to 0.0C. If you look at the graph this equates to an SOC of anything from ~98% to ~99%+ if charging at 3.45V/cell. If I pick a lower charge voltage of 3.4V/cell (13.6V for 12V battery) I can get a final SOC from ~85% to~96%+ with the controller going into the absorb phase and limiting the rate that the battery is charged at ~85% SOC. If I were charging at a rate of 0.2C this would be ~70%, not much good in the middle of winter!

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

Comments

-

I would add that the opposite problem, is with a large system in summer with long hours. One has to be very careful that the system doesn't exceed 100% SoC. Both of these scenarios are solved by a BMS interfacing with the power system but even then, it is not an "easy" thing to do.

"we go where power lines don't" Sierra Nevada mountain area

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

With a standard solar charge controller this scenario is avoided by having the controller switch to a lower float voltage of 3.35V/cell (13.4V for a 12V battery) after a short absorb time of half an hour or preferably when the charge current reduces to around C/20-C/50.Dave Angelini said:I would add that the opposite problem, is with a large system in summer with long hours. One has to be very careful that the don't exceed 100% SoC. Both of these scenarios are solved by a BMS interfacing with the power system but even then, it is not an "easy" thing to do.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

It looks to me like whenever you read the voltage, you need to make an adjustment for whatever the recent (time period?) charging current is. Similar to a temperature coefficient with lead acid batteries.

> all one has to do is charge at a fixed rate of 0.25C and terminate the charge when the voltage reaches 3.45V/cell

Sounds like it would lead to overcharging (more than your desired 90% SOC) in a realistic solar case - what happens when you terminate the charge, loads draw down the battery slightly and then charging starts again. The average charging rate is now quite low. But maybe OK if you lower the voltage after the initial termination.

Some graphs that make more sense to me:

http://en.winston-battery.com/index.php/products/power-battery/item/wb-lyp200ahab?category_id=176

(this one seems to suggest just using 4.0V, resulting in 105%-115% SOC. But other sources say this is too high.)

https://us.v-cdn.net/6024911/uploads/editor/gd/5k1jkfzmtc1c.jpg

(shows that high charge rates take awhile to be accepted)I am available for custom hardware/firmware development

-

One major problem I see with thinking that one can accurately and consistently charge an LFP battery to 90% or less using solar power is that one might think that because the battery is so far from being fully charged that you don't need to worry about monitoring the individual cell voltages or how well balanced the battery is when in reality your battery may on very rare occasions with a particular set of charging conditions get very close to 100% full .

Another problem is that even if you could reliably charge to 90% that you could get a fault in one of the cells in the battery whereby it would loose more than 10% of its capacity (similar to a lead acid battery loosing one of its plates due to corrosion/vibration) in which case charging to 90% would charge the damaged cell over 100% and out of its safe operating zone. You would not detect this fault unless you have some sort of battery management/monitoring system.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

I really am referring to a large system over 5 kw of solar, multiple mppts, large loads, and a BMS based battery that takes care of itself all year long for 15 years.

I do see your problem Simon."we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

I can think of some possible solutions (for a smart charger):

a) monitor charge current over the last hour, find the lowest value and use that to pick a proper charge voltage.

b) use coulomb counting and only use the higher charging voltage when SOC is < 80%. Then switch to the low voltage.

Or

c) just use the lower (0C) charging voltage and accept the fact that the charge will be lower current, taking longer to charge. But it will eventually reach the desired SOC.

IMO, individual cell monitoring is always a good idea.I am available for custom hardware/firmware development

-

As long as the battery BMS communicates with the power system this is what is happening with the Conext Bridge for Schneider and I would assume with the Outback Skybox.jonr said:I can think of a couple of possible solutions (for a smart charger):

a) monitor charge current over the last hour, find the lowest value and use that to pick a safe charge voltage.

b) use coulomb counting and only use the higher charging voltage when SOC is < 80%. Then switch to an always safe voltage.

For Simon in winter your suggestion might help. It needs to be fast, accurate, react to clouds and loads, and be reliable. It probably would need a failsafe mode at lower V and I."we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

I think there is only a problem if you feel it is necessary to charge an LFP battery to no more than 90% with solar power. There is not a problem if you accept that it is impractical and unnecessary to charge an LFP battery to only 90%.

Set the bulk and absorb voltage to around 3.45V/cell (13.8V for 12V battery) and assume that your battery could get to ~99% full and make sure that it is either manually or automatically balanced so that if it gets to ~99%SOC that the individual cell voltages will still be within the safe operating range. As a backup have a BMS that will shut down the solar charge controller or disconnect the solar panels from the charge controller if any of the individual cell voltages start to go outside the safe operating zone.

I have not seen any evidence that keeping an LFP battery at a state of charge greater than 90% for several hours a day if the battery is constantly in use as in an off grid system will greatly decrease the lifespan of the battery. I have seen evidence that keeping an LFP battery at >70%SOC for extended periods while not being used or keeping lithium cobalt batteries at high states of charge will decrease their lifespan significantly.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

From reports I've seen, stopping at 90% would provide longer life. But not clear how much more.

It would be interesting to see some numbers in terms of how much faster it is to use fast charging (ie, higher voltage while using high currents). Looks like most people are using slow charging for solar (ie, use a single max voltage with no adjustment for current).

I'll throw out another voltage adjustment that I think is always valid (for any system). If you know the resistance of the string and the current, you can safely add the resulting voltage drop. For example, if the string has 10 milli-ohms of resistance and you are currently charging at 30A, then .010 * 30 = .3V. So you could charge at 3.45V/cell * cells + .3V without the internals of any cell (assuming that are balanced) seeing more than 3.45V. Or just pause charging while checking the voltage.I am available for custom hardware/firmware development

-

Simon, if this is defensible,...

keeping an LFP battery at >70%SOC for extended periods while not being used ................. will decrease their lifespan significantly.?

What is the recommended SoC % that the batteries should be 'hibernating ' at? 70 %, or lower than that?

KID #51B 4s 140W to 24V 900Ah C&D AGM

CL#29032 FW 2126/ 2073/ 2133 175A E-Panel WBjr, 3 x 4s 140W to 24V 900Ah C&D AGM

Cotek ST1500W 24V Inverter,OmniCharge 3024,

2 x Cisco WRT54GL i/c DD-WRT Rtr & Bridge,

Eu3/2/1000i Gens, 1680W & E-Panel/WBjr to come, CL #647 asleep

West Chilcotin, BC, Canada -

I've heard 40%. And keep them cool.

I am available for custom hardware/firmware development

-

That only holds true while 30A is flowing. Less than 30A, and the voltage drop becomes less, and the cells see the higher voltage.jonr said:..........

.....For example, if the string has 10 milli-ohms of resistance and you are currently charging at 30A, then .010 * 30 = .3V. So you could charge at 3.45V/cell * cells + .3V without the internals of any cell (assuming that are balanced) seeing more than 3.45V. Or just pause charging while checking the voltage.

Maybe some engineering firm, could take their standard MPPT charger, and allow it's SW to halt charging for a second, measure true pack voltage, and then resume if needed.

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

Correct, as stated, it is only useful with the current (ie, measured, right now) charge rate - not any other charge rate. In the example, not doing the adjustment would result in 12V of batteries actually seeing 3.375V (3.45-.075) per cell. That's an important difference when dealing with lithiums.

Pausing charging can create a problem with a load causing a similar (but opposite direction) effect - so you probably end up doing the adjustment anyway.I am available for custom hardware/firmware development

-

The graphs from this excellent paper http://jes.ecsdl.org/content/163/9/A1872.full.pdf give a good indication.westbranch said:Simon, if this is defensible,...

keeping an LFP battery at >70%SOC for extended periods while not being used ................. will decrease their lifespan significantly.?

What is the recommended SoC % that the batteries should be 'hibernating ' at? 70 %, or lower than that?

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

That suggests that time at full charge is a critical factor. Which suggests yet another lithium charging scheme. Charge to 100% (because this is easy to detect from the sharp voltage rise) and then immediately drain it back down to 90% (using coulomb counting). Might be almost as good as just charging to 90%.

I am available for custom hardware/firmware development

-

jonr said:From reports I've seen, stopping at 90% would provide longer life. But not clear how much more.

It would be interesting to see some numbers in terms of how much faster it is to use fast charging (ie, higher voltage while using high currents). Looks like most people are using slow charging for solar (ie, use a single max voltage with no adjustment for current).

I agree that it is highly likely that charging to only 90% will increase the lifespan of an LFP battery. I would also like to know how much difference. Myself and a number of other people with off grid systems with batteries between 4-7 years old are seeing little if any drop in the storage capacity of their batteries even though the are charging to 3.45-3.5V/cell. The 4 year old cell that I did some charge/discharge tests on still has a storage capacity of 90Ah. Unfortunately I don't have any baseline data for it but think it is more than likely that it has lost a few percent of capacity since new.

Slow charge and discharge rates increase the life of LFP batteries. As a guide keeping charge rates below 0.5C and discharge rates below 1C is a good idea. Off grid systems with LFP batteries usually have 2-3 days storage capacity so even if you have a day with no energy input from the solar panels you at most only have to replace C/2-C/3 to fully recharge the battery in the following days. Even in winter this recharge will be happening over several hours which cuts the maximum necessary charge rates to less than ~C/4. At these sort of charge rates the voltage rise due to the internal battery resistance is less than 0.05V/cell (0.2V for a 12V battery).

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

The LFP battery graph suggests to me that you would have to reduce the SOC to below 70% to make any meaningful difference to the lifespan of the battery if what you are saying is correct.jonr said:That suggests that time at full charge is a critical factor. Which suggests yet another lithium charging scheme. Charge to 100% (because this is easy to detect from the sharp voltage rise) and then immediately drain it back down to 90% (using coulomb counting). Might be almost as good as just charging to 90%.

My understanding is that a major aging mechanism that is in play at an SOC of >70% is lithium plating at the electrolyte side of the SEI layer. This is a slow process as the electrons have to tunnel their way through the SEI layer which has very low electron conductivity from the graphite anode. This process stops and goes into reverse if current is being drawn from the battery.

My theory as to why I am not seeing the reduction in capacity that should be happening at the high SOC levels that my battery is subjected to is that when the battery is on float charge there are usually loads turning on and off that will temporarily draw current from the battery which will greatly reduce this lithium plating.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

One my take-aways from the monster Crusiers Forum LFP thread is thatkarrak said:One major problem I see with thinking that one can accurately and consistently charge an LFP battery to 90% or less using solar power is that one might think that because the battery is so far from being fully charged that you don't need to worry about monitoring the individual cell voltages or how well balanced the battery is when in reality your battery may on very rare occasions with a particular set of charging conditions get very close to 100% full .- an initially balanced bank

- used at fractional-C charge/discharge rates (as when charged with common RV solar installations, my particular interest)

- charged to 3.45v/cell then stopped

- kept "between the knees"

<shrug> I don't have any practical experience yet. My setup is still Pb.

-

I got to peak at the LG testing @15 years and my take in reduction of capacity " if realistic safeguards are in place" is how the battery is built.

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

'Simon, And it fits in with the old adage of ' 'not running electronic devices near/at their maximum limit''

Dave, are there working links for those ones you posted above, '@15 years' and 'video' ?

KID #51B 4s 140W to 24V 900Ah C&D AGM

CL#29032 FW 2126/ 2073/ 2133 175A E-Panel WBjr, 3 x 4s 140W to 24V 900Ah C&D AGM

Cotek ST1500W 24V Inverter,OmniCharge 3024,

2 x Cisco WRT54GL i/c DD-WRT Rtr & Bridge,

Eu3/2/1000i Gens, 1680W & E-Panel/WBjr to come, CL #647 asleep

West Chilcotin, BC, Canada -

See thread 27 for the LG link

http://forum.solar-electric.com/discussion/351297/conext-bridge-for-xw-li-ions-from-lg-and-hoppecke-announced-for-2nd-half-2017

The life link is from LG and their service manual that is not out yet from LG or Schneider. I can't link that yet. They used HALT testing and one of the LG's at Schneider has been cycled by "crazy people" since mid 2016 and still has 99% of its life left. The list below is what the marriage is all about.

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

YES!! What you are witnessing is something that I've been harping on for years - being "application specific" when it comes to LFP.- an initially balanced bank

- used at fractional-C charge/discharge rates (as when charged with common RV solar installations, my particular interest)

- charged to 3.45v/cell then stopped

- kept "between the knees"

<shrug> I don't have any practical experience yet. My setup is still Pb.

Their needs are very close to ours, and we aren't even floating in a corrosive marine environment, or the typical marine regulator / alternator / solar charging infrastructure. KISS works for our application, but not for EV / RC etc.

Thus, we don't have to go absolutely bananas with precise balancing. *Reasonably close* is the watchword - in OUR application -, although you can get nutty if you want to. But when you are staying between the knees, reasonable is fine.

Some things don't become apparent until you experiment. For example: if you OVER-estimate your battery capacity needs, the only penalty you'll suffer is the higher initial out of pocket expense. What you get accidentally is more autonomy, or just the ability to run larger loads.

Overstimate a Pb bank capacity, and not have the solar charge power to adequately charge it to 100% often, means you are killing your batteries until you fix the solar problem. With an oversized LFP bank, all you'll do is run in an even narrower window of charge/discharge, lengthening the life of the bank. Wallet will suffer initially of course, but you aren't immediately penalized with battery abuse.

-

YES!! I love it. What we borrow from our EV friends (not OUR application!) who favor fast charging >.5C, high voltages for quick turnarounds 3.6v per cell was that "full capacity" charging (canonically determined by reaching 0.05C or less during absorb), was a problem. Phase delay (measured terminal voltages not being "true") because of the quick chemical reactions meant that the battery when rested was never fully charged to capacity, despite the <.05C or less taper current trigger. Thus formulas involving charge current, taper current, and absorb voltages were used to get some idea of predictable accuracy.karrak said:The big problem is that if you are charging from solar the charge rate is not constant. In my case it can go from a maximum of ~0.12C to 0.0C. If you look at the graph this equates to an SOC of anything from ~98% to ~99%+ if charging at 3.45V/cell. If I pick a lower charge voltage of 3.4V/cell (13.6V for 12V battery) I can get a final SOC from ~85% to~96%+ with the controller going into the absorb phase and limiting the rate that the battery is charged at ~85% SOC. If I were charging at a rate of 0.2C this would be ~70%, not much good in the middle of winter!

On the other hand is charging at a very low current rate - which you rightly point out being an issue with solar. To get to the point, if you try and charge at say the "finished absorb" current value of 0.05 or less, your cells will have a VERY hard time exceeding 3.45v! In essence, at this very low rate, you are "absorbing" your way to full. Bad way to express it, but the key here is that at low charge rates, we don't suffer so much from voltage phase-delay like the rapid-charge EV guys do.

The key issue was that unlike fast-charge EV's, our available unreliable solar current could drop to precipitously low rates, even if you actually wanted to or have the ability to charge at 1C! That solar current drop risk you take meant that one would STILL want to keep the absorb voltages low, like 3.45v per cell. Again, at those low rates, you'll have a hard time getting it beyond 3.45 *under charge* anyway.

Thus, setting your charger for 3.6v per cell, when <0.05C charge current was available, and using a bms looking for a "high" voltage to determine when to stop meant that it would keep the cells on full charge much longer than they needed to be. TIME at full charge is extended artificially, never being able to reach the preset!

WARNING: after testing, what I did find out with -smaller- cells treated this way, was that YES YOU WOULD EVENTUALLY exceed 3.45v at low charge currents - but not from normal charging! What happens now is that after some time, the cells are running away with secondary reactions, not charging.

Catch-22: It is at this point, that a bms with a high voltage setpoint would yes, trigger a shutoff - but not from the cells being nicely charged to full, but from *runaway* reactions. This runaway is not something you'd likely see with large cells, but nevertheless it is damaging the cells.

Sorry - very long story - you found that low absorb voltage, under our application subject to unreliable solar conditions, was the ideal way to deal with the banks.

-

Reminder: What does "reasonably close" balancing look like?

Even though we intend to operate at low absorb voltages normally, an *initial* reasonably close top-balance can be done:

* Charge the bank at 3.6v per cell absorb. That's 14.4v for a 4S battery.

* Watch the cells - no cell should be lower than 3.45v or higher than 3.6v near the end of charge.

* When the absorb current drops to 0.05C (say 5A for a 100ah bank), no cell should be lower or higher than 0.10v from each other. In practice, I prefer no more than 0.07v difference across the board. Done.

The payoff here is that unlike a bleeder-type simplistic balancer, no cell is held artificially high while waiting for the rest to catch up. Amazingly, I've seen people "balance" for 3 days! That's 3 days of holding a cell artificially high. Instant aging. Do something like this, even for 10 minutes a cycle, that ADDS UP over the course of years, and prematurely ages the bank. But oh, look at how the voltages of each cell are now withing 0.00001v of each other!

NOW, under normal conditions, drop your regular absorb voltage for cycling to 3.45 - 3.5v per cell. (13.8v to perhaps 14.0v for a slightly quicker charge).

100% charge is reached when absorb current drops to 0.05C. But you don't want to go there often, so pull the charge a bit beforehand, or have a bank and load combination that will never get fully charged in the first place.

-

So I have my sbms at factory settings 3.55 v first cell to reach stops charging 3.399 starts charging 2.8 v first cell to reach will shut off load and inverter won't turn back on till first cell hits 3.20 volts and there all adjustable with time also like 1 second under voltage lock, I hope my cells will last 12 years, and have about 26 amps max charge to a 200 amp bank hope to put 4-250 w panels instead of the 3-300 w panels soon to go to 36 amps max.200ah LiFePO4 24v Electrodacus Sbms40 quad breaker chest freezer to fridge- Samlex PST 1524 - Samlex pst3024 - 1hp shallow well pump-Marey 4.3 GPM on demand waterheater - mama bear Fisher wood burning stove, 30" fridgarair oven ,fridegaire dishwasher Unique 290l stainless D.C. Fridge-unique 120l portable fridge/freezer

-

So here is a screen shot from my phone from the built in wifi200ah LiFePO4 24v Electrodacus Sbms40 quad breaker chest freezer to fridge- Samlex PST 1524 - Samlex pst3024 - 1hp shallow well pump-Marey 4.3 GPM on demand waterheater - mama bear Fisher wood burning stove, 30" fridgarair oven ,fridegaire dishwasher Unique 290l stainless D.C. Fridge-unique 120l portable fridge/freezer

-

Very useful thread. Thanks all. Now step ahead 18 months and we have increased use of integrated 12V LFP batteries like Lifeblue and Battleborn and similar with internal BMS. Seemingly these BMS pretty much only protect against severe abuse (charging over 16V, etc.). Some have built-in SOC monitoring like the Lifeblue (via bluetooth). It seems the SOC does not account for the small internal losses in an LFP and thus increasingly reads higher than actual if the battery is cycled daily and charged with solar that may not get the battery back to 100% for weeks on end. In my case the SOC was indicating 25% when actual was well below 5%. It seems the SOC is reset only by a re-charge to a true 100%. I.e., the SOC monitor hits an indicated 100% but charging is continued until voltage reaches 14.4 to 14.6V. Unfortunately with the Lifeblue I had to figure this out on my own (I had 300W of solar and a 300 AH battery so rarely saw 100% in the winter). My RV now has 600W of solar so often gets to a true 100% and I have a simple 60A charger that is only used when SOC gets below 20% or if I think I need to get to 100% to reset the SOC monitor.Anyway, my point is that this constraint pretty much precludes limiting the battery to 90% charge, at least in any automatic manner. I do sometimes set my charge controllers to a lower voltage (14V) for a week if the weather prediction is good and I don't need to be at 100% to prepare for 3 or 4 days of rain (have a generator but hate using it).

-

You are right, all the BMSes I am aware of need the voltage to reach whatever they define as the full voltage and some would also need the charge current to have tapered off before they will reset the SOC counter.Some don't make any allowance for the battery losses and will have to be reset on a regular basis to maintain any accuracy. Some allow you to set the battery losses and will take this into account when calculating the SOC.The best setup is for the BMS/SOC meter to learn what the losses are and vary the correction accordingly. This is the way my BMS software calculates the SOC and I find the SOC remains accurate over many weeks.I am not sure if any of the commercial BMSes/SOC counters will automatically adjust for the battery losses. It would be a good feature to look for.SimonOff-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

Had a frank discussion with an engineer from Battleborne, his quote was despite the claims of 100% charge/discharge, there are safety parameters included, in other words the actual capacity is greater than the advertised capacity to provide a safty net, if you like, which prevents over/under, charging/dischargeing. They confirmed the battery is made up of small cells rather than prysmatic cells , sourced externally, they were very forthcoming with information despite my fishing expodition, they appear to be strait up with regards to information.

With LFP, based on obversations, the 100% fully charged state is a factor not woth bothering with, the difference between 95% and 100% occurs in a matter of minutes or seconds, depending on charge current, therefore irrelevant for the most part, the long wait ends in an orgamasic conclusion, voltage climbs very rapidly in the termination stage. The discharge curve on the other hand is the reverse of the charging, ending in in an anticlimactic situation should there be no protection, in the form of a BMS, voltage will plummet if unguarded which can result in cell damage.

These parameters are explained in detail should one look for information, using drop in replacements will, for the most part eliminate variables, but that's no fun, depending on what fun is defined as.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

This is a great discussion, very helpful for me who just ordered LFP batteries and now trying to come to terms with how best to charge and protect them. Occurs to me that there are LFP-specific chargers out there so engineers have addressed ideal charging parameters for LFP. Is there a particular unit that seems to be very good? Has anybody here looked into the charge parameters they use and then tried to duplicate those with a standard charger for flooded batteries?I have a Tristar 150V 60A mppt that I think could do the job if I can come to terms with how high and how long to run the absorb and also whether or not to use a float cycle and if so at what setting. A cool thing about the LFP batteries is how constant their voltage is between 10 and 90%SOC but that makes the V cutoffs and targets maybe a little tougher to specify.I like the idea of programming it between the knees. Was thinking of 3.4 or 3.45 absorb target. THe low end cutoff will have to be controlled by my inverter and I was guessing around 2.8 or 3 V for that.You guys understand these battery chemistries and have a lot more experience that I do so I'd appreciate your thoughts. I have read everything I can get my hands on but still haven't been able to really nail down specific targets that are agreed on by the "ones who know".I should say that I am off grid with 3.6kW panels and will have 800Ah batteries with (16s4P) with continuous balancers on the 16 parallel groups. In the sunny southwest and have been getting by on 470Ah lead-acid bank til now but struggling when the sun is gone for 2-3 days.12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff)

Categories

- All Categories

- 233 Forum & Website

- 141 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 900 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed