Charging LFP (LiFePO4) batteries to 90% SOC, or not

Comments

-

Hi Dave,

The Tristar controller will work ok with the LFP bank. 3.4V to 3.45V per cell absorb setting is ok also. I'd recommend a float setting of 3.33V to 3.35V per cell. With this bank, most of the power is available between 53V and 52V while discharging. This is the flat part of the discharge curve. I would not recommend discharging lowering below 3 volts per cell on a top balanced bank. I use 3.15V per cell as the bottom on my own battery bank. Better to be safe than sorry.

Rick4480W PV, MNE175DR-TR, MN Classic 150, Outback Radian GS4048A, Mate3, 51.2V 360AH nominal LiFePO4, Kohler Pro 5.2E genset. -

Thank you Rick. How long do you absorb for? I think the idea is just to get the cell V to the absorb setting and cut it off but I didn't know if that means a 1, 15, or 30 minute absorb time because I don't know if when the cells first hit absorb V if that means they are actually holding that V or it takes a few minutes to truly be at that V?I've also heard that an occasional full, 100% charge is a good idea. Have you heard that? If so, I was thinking a good way to achieve that would be a periodic equalize to 3.65V for a couple of minutes. What do you think? How often, monthly, every two months...?one other minor point I have been wondering about is how do people lap the busbars? For the long parallel runs, I will have 2 busbars connected to each terminal and I wonder if it matters if I just piggyback them or alternate top and bottom as they go along? And for the series connections, I will have two or three busbars stacked but will also have a busbar perpendicular to them for the parallel run. I'd like to see pix of how others have done these but so far have not found any. I'm also curious if people use any dielectric grease or just attach the busbars dry to the terminals?I ordered my batteries thru Alibaba from Simon at HuanHuan yesterday. My wife and friends think I am crazy but I am optimistic and the cost was less than a third of what i'd have to pay here.12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff)

-

It's best to end absorb with the "end amps" setting, but if the controller doesn't have that function, then an absorb time of 15 to 30 minutes should do. This can be tweaked later to suit your needs.

With a constantly balancing BMS there is no reason to charge above absorb voltage.

I'd overlap the bus bars in a way that keeps them level, but might need extra washers on the parallel connections.

I don't use the grease, not necessary in my opinion.

I haven't seen any photos or diagrams of series parallel configurations similar to what you've described.

From what I've seen, LFP prices have been dropping lately.4480W PV, MNE175DR-TR, MN Classic 150, Outback Radian GS4048A, Mate3, 51.2V 360AH nominal LiFePO4, Kohler Pro 5.2E genset. -

Thanks much, Rick

12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

This is the method I used for a 4P 8S arrangement, I made up some bus bars out of flat stock copper, 6 with 8 holes, 2 with 4 holes, 2 with 5 holes and 1 with 2 holes. There is a snail space between each cell which is not shown, this keeps the positive and negative main terminals at one end. To build a 16S bank would be double this arrangement, the only double stacked terminals are at the series link. Note the bus with 5 holes go on the outputs which are not shown, the extra hole is to mount a terminal lug.

My settings were taken from recommendations by Simpliphi for Schneider equipment, bulk/absorb 28V, absorption time 6 minutes, float 27V, EQ disabled, no temperature compensation, Ah value input to charger 50% of actual. LBCO is set via BMS at 25V, or 24V inverter's, maximum, the 2% of capacity to end absorption never comes into play because current is still at maximum and timed out after 6 minutes.

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

Generally, LFP batteries do NOT use an absorb time. I've not played with minimum absorb time, but the tristarMPPT is changeable with the MSView software & the right cableThere is something tricky about setting voltages so trickle charge DOES NOT happen to LFP once they are charged.Hopefully the LFP gurus will answer thisPowerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

mike95490 said:Generally, LFP batteries do NOT use an absorb time. I've not played with minimum absorb time, but the tristarMPPT is changeable with the MSView software & the right cableThere is something tricky about setting voltages so trickle charge DOES NOT happen to LFP once they are charged.Hopefully the LFP gurus will answer this

True LFP don't need absorption but it is a stage in the design criteria of the controller that is needed a value, along with a means of transitioning to float, hence the short duration programed. Why Simpliphi/Schneider came up with 6 minutes is unknown to me but in reality there is not much that would happen in that period, one or six minutes wouldn make negligible difference.

Because the voltage at float is substantially below the fully charged voltage, along with the fact the charging source regulates the setpoint, there is no problem with trickle charging. When solar charging the voltage may sag when large loads are applied but the controller will makeup the loss and stabilize at the float setpoint. Having a BMS would protect the battery should something fail and there is an over or undr voltage situation.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

mcgivor said:This is the method I used for a 4P 8S arrangement, I made up some bus bars out of flat stock copper, 6 with 8 holes, 2 with 4 holes, 2 with 5 holes and 1 with 2 holes. There is a snail space between each cell which is not shown, this keeps the positive and negative main terminals at one end. To build a 16S bank would be double this arrangement, the only double stacked terminals are at the series link. Note the bus with 5 holes go on the outputs which are not shown, the extra hole is to mount a terminal lug.

My settings were taken from recommendations by Simpliphi for Schneider equipment, bulk/absorb 28V, absorption time 6 minutes, float 27V, EQ disabled, no temperature compensation, Ah value input to charger 50% of actual. LBCO is set via BMS at 25V, or 24V inverter's, maximum, the 2% of capacity to end absorption never comes into play because current is still at maximum and timed out after 6 minutes.I like your DIY copper busbars, could probably use aluminum too, I think, and I can get AL bar from Home Depot. I guess your Absorb equates to 3.5V per cell which I think is a bit higher than I'll try but I lik using 6 minutes since somebody must have had a reason for that. i'm still trying to sort out what a good float value is, not sure what factors need to be considered for that. And, I'm realizing that other than the cutoff volt built into each cell, my LBCO will be controlled by my inverter and it makes me nervous not to have a back up for that. I suppose that is an argument for using a BMS, which I was not planning on.

12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

> I'd recommend a float setting of 3.33V to 3.35V per cell

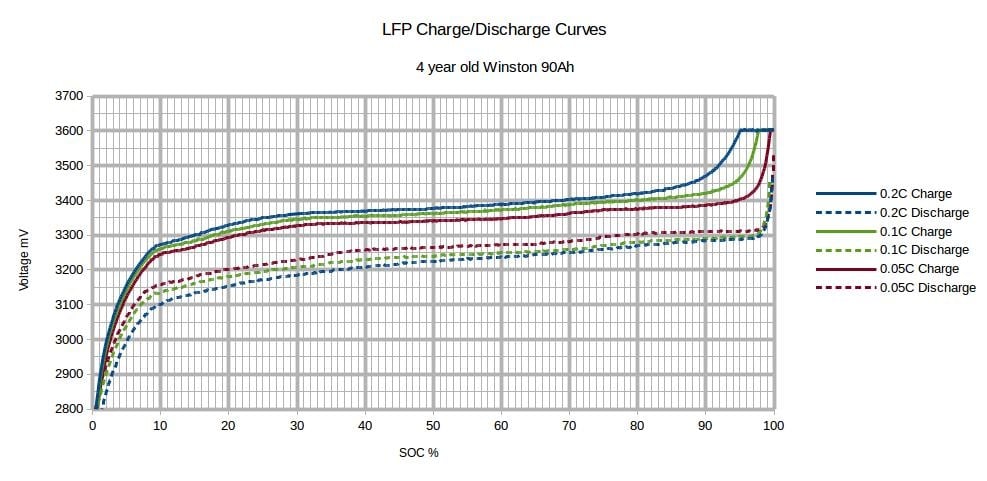

Look at the graph in response #17 and you will see that this will allow the battery to drop to about 35% SOC. This is fine for storage, but not good if you want to use the battery.I am available for custom hardware/firmware development

-

@Dave

Its not a good idea to use aluminum bus bars. Oxidation will be a problem, it will seriously degrade conductivity. Make copper bus bars and save yourself the trouble. You will be glad you did. Incidentally, there is no safe cut off voltage built into prismatic cells. If the voltage drops down to 2.5V, the cell will be unrecoverable.

Rick4480W PV, MNE175DR-TR, MN Classic 150, Outback Radian GS4048A, Mate3, 51.2V 360AH nominal LiFePO4, Kohler Pro 5.2E genset. -

FWIW, my guess on why 6mins is the chosen absorb time:

The time would normally be set to 'X', or 'X.y' hours in a lead acid application. This value may be stored as an integer and divisor (eg 2.5hrs stored as 25 internally). With a divisor of 10 (which I've seen in modbus MN & MS controllers), 6 minutes can be stored accurately (60÷6= 1/10hr = 0.1hr, stored as an int = 1). A minutes value resulting in a decimal fraction with >1 fractional digit (eg 5mins is 1/12hr=0.0833333... hr) couldn't.

In other words, (if I'm on the right track), 6mins may be the shortest non-zero absorb time it's possible to set.Off-grid.

Main system ~4kw panels into 2xMNClassic150 370ah 48v bank 2xOutback 3548 inverter 120v + 240v autotransformer

Night system ~1kw panels into 1xMNClassic150 700ah 12v bank morningstar 300w inverter -

That may appear to be the case, but over three years experience with a 195AH LFP bank has taught me that it's about 90% SOC or better. Below is a graphic from My Midinte showing the Classic 150 finishing absorb at 54.8V (3.425V per cell) then dropping to float at 53.6V (3.35V per cell). It holds float for 30 to 40 minutes. SOC starts to drop when the bank begins to fall below float voltage.This graphic displays a 26 hour period.jonr said:> I'd recommend a float setting of 3.33V to 3.35V per cell

Look at the graph in response #17 and you will see that this will allow the battery to drop to about 35% SOC. This is fine for storage, but not good if you want to use the battery.

4480W PV, MNE175DR-TR, MN Classic 150, Outback Radian GS4048A, Mate3, 51.2V 360AH nominal LiFePO4, Kohler Pro 5.2E genset. -

@Dave As I mentioned I used SimpliPhi's recomendations for use with Schneider gear as a guide, my assumption was the collaboration between the two must have some validity. They also have information for use with Outback equipment that differs somewhat, possibly due to setting restrictions, they stay an absorbtion which is counter to most reasoning.

Attached is a pdf similar to what I used as a guide, however as you have Morningstar the settings may be more flexible using MS View via a meter bus adapter available from our host's store. Morningstar tech support is excellent as you may know, they would be a useful resource I would assume.

During charging my observed battery voltage for the six minutes is in fact 27.4 V or 3.425 V per cell due to voltage drop, they have been in service for 14 months without any hiccups. Initially I did use aluminum for bus bar material without any issues related to oxidation, with regular checks for voltage drop, terminal to busbar of every cell, but there are so many alloys which may make a difference. Copper is superior but was not locally available at the time, as soon as I found a source I imported flat stock copper, far easier than searching locally in Thailand. @Raj174 was extremely helpful along with @karrak, who apparently seems to have gone silent as of late, there are very few here who have made the switch to a DIY bank, so the knowledge/experience base is pretty slim, you won't however have any regrets other than having not switched sooner.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

@Raj174 I agree that it depends on the use and charging scenario. Most importantly, what it takes to trigger the system to stop float charging and apply a higher voltage. Too often and it over-charges, too seldom and SOC can get way too low.

I am available for custom hardware/firmware development

-

Alrighty then.4480W PV, MNE175DR-TR, MN Classic 150, Outback Radian GS4048A, Mate3, 51.2V 360AH nominal LiFePO4, Kohler Pro 5.2E genset.

-

mcgivor said:This is the method I used for a 4P 8S arrangement, I made up some bus bars out of flat stock copper, 6 with 8 holes, 2 with 4 holes, 2 with 5 holes and 1 with 2 holes. There is a snail space between each cell which is not shown, this keeps the positive and negative main terminals at one end. To build a 16S bank would be double this arrangement, the only double stacked terminals are at the series link. Note the bus with 5 holes go on the outputs which are not shown, the extra hole is to mount a terminal lug.mcgivor said:@Dave As I mentioned I used SimpliPhi's recomendations for use with Schneider gear as a guide, my assumption was the collaboration between the two must have some validity. They also have information for use with Outback equipment that differs somewhat, possibly due to setting restrictions, they stay an absorbtion which is counter to most reasoning.

Attached is a pdf similar to what I used as a guide, however as you have Morningstar the settings may be more flexible using MS View via a meter bus adapter available from our host's store. Morningstar tech support is excellent as you may know, they would be a useful resource I would assume.

During charging my observed battery voltage for the six minutes is in fact 27.4 V or 3.425 V per cell due to voltage drop, they have been in service for 14 months without any hiccups. Initially I did use aluminum for bus bar material without any issues related to oxidation, with regular checks for voltage drop, terminal to busbar of every cell, but there are so many alloys which may make a difference. Copper is superior but was not locally available at the time, as soon as I found a source I imported flat stock copper, far easier than searching locally in Thailand. @Raj174 was extremely helpful along with @karrak, who apparently seems to have gone silent as of late, there are very few here who have made the switch to a DIY bank, so the knowledge/experience base is pretty slim, you won't however have any regrets other than having not switched sooner.Thanks so much @mcgivor (i don't know how to make this an active link to you??) all this information is super helpful. I've read the recent stuff from Raj too but I am still struggling to come to a conclusion about float setting although I am inclined to adopt his 3.35 float setting based on his experience.Now, I'm trying to design a simple low and high voltage cutoff system. the inverter has a built in cutoff at 48V but i'd like some redundancy and a primary cutoff more like 50.4V. the charge controller should prevent overcharging unless the controller has a hiccup or fails and then i want something to cut the power from the panels before any damage is done to the batteries. I was not planning on using a BMS so i am trying to see what else i could crib together to provide the upper and lower cutoffs in case the primary cutoffs fail.12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

karrak said:jonr said:From reports I've seen, stopping at 90% would provide longer life. But not clear how much more.

It would be interesting to see some numbers in terms of how much faster it is to use fast charging (ie, higher voltage while using high currents). Looks like most people are using slow charging for solar (ie, use a single max voltage with no adjustment for current).

I agree that it is highly likely that charging to only 90% will increase the lifespan of an LFP battery. I would also like to know how much difference. Myself and a number of other people with off grid systems with batteries between 4-7 years old are seeing little if any drop in the storage capacity of their batteries even though the are charging to 3.45-3.5V/cell. The 4 year old cell that I did some charge/discharge tests on still has a storage capacity of 90Ah. Unfortunately I don't have any baseline data for it but think it is more than likely that it has lost a few percent of capacity since new.

Slow charge and discharge rates increase the life of LFP batteries. As a guide keeping charge rates below 0.5C and discharge rates below 1C is a good idea. Off grid systems with LFP batteries usually have 2-3 days storage capacity so even if you have a day with no energy input from the solar panels you at most only have to replace C/2-C/3 to fully recharge the battery in the following days. Even in winter this recharge will be happening over several hours which cuts the maximum necessary charge rates to less than ~C/4. At these sort of charge rates the voltage rise due to the internal battery resistance is less than 0.05V/cell (0.2V for a 12V battery).

SimonThanks @karrak so much for gathering these data and posting here. Now that my bank is set up, this is really helpful in setting the charge and disconnect points. The more I look at it the more I get out of it.This blog is a great resource, lots of helpful and knowledgeable people made a technically challenging project possible for me. Thank you all!12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

Back again with some real-world observations and questions. Bank is balancing well enough that at absorb V, there is rarely more than 30mV spread and less than that at lower V. In my 4p16s arrangement, I've been absorbing at 55V (3.4375) for 6 minutes then dropping to 54.1V (3.38) for float. Charge rates are typically 0.05C or less with the highest I have ever seen at about 0.056C so I assume that when the batteries hit absorb V, they are truly at that V. My 800Ah bank is oversized for >90% of the time but I wanted the extra capacity for long storms and other situations that we have rarely and didn't want to need a generator.Here in the sunny southwest, the system gets the full charge (6 min Absorb at 55V) most days and only draws down about 10% at night so the system is maybe running like 87-97% range.Will that shallow cycling near the top end likely reduce the life span of the batteries? I've read this thread many times and I cannot reach a conclusion. If it would reduce their lifespan, would I be better off going to a bit lower Absorb, like maybe 3.4V/cell?Thanks for opinions and experience! The postings and PMs from people on this board have been a lifesaver through this process; best resource I have found.

12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

Looking at the voltage settings and absorbtion time, it would all appear to be good, shallow cycles would be of little concern, since you are not attempting 100% charge you are in safe terrotory, my opinion naturally. The shallow discharge would benefit the life expectancy along with offering added insurance of power after a day or two of little sun.

Going by your signature the array should be sufficient in all but the worst case scenario, but being in a partial state of charge for a few days is not a problem, LFP accept maximum current without the long absorption cycle, so charging is very efficient

As far as generator charging is concerned the only time in 14 months I've used it is to verify it works if ever needed, my question to you is, are you happy with the performance so far? My experience has been nothing but positive, hope yours is the same.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

Thank you @mcgivor, that's comforting to hear. yes, I am loving it and now that it seems I am getting close to being dialed in am looking forward to not having to worry about it much going forward other than some tweaks that I will wait for and do all at once. After maintaining those FLA and always worrying about not having them at full charge, the flexibility these LFP bring is terrific. Just inherently feels like a much much better system and the cost I paid for the LFP was very competitive with what a replacement FLA system would have cost. No comparison on performance. I used to get surges when a big draw would come on line but the LFPs handle it so much better that we rarely see any effect now. I thought I had changed my signature to show the new battery system, hopefully it's updated now.

12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

@Dave Took a look at the Choice BMS300 which is in fact a Chargery product, I have a similar one primarily for its display being that is a passive type with externally driven relays, my primary BMS is the one in the attached pdf. The external relay drivers of the Chargery are used to drive linear actuators to trip circuit breakers if the primary BMS were to fail, a reserve parachute of sorts.

Good to hear you're happy with your decision, they do indeed outperform LA in almost every aspect.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

Thanks @mcgivor, I wrote Jason Wang, who is listed as the contact at Chargery, and copied Chris at Electric Car Parts Company describing the issues I am seeing with the Choice BMS300 (also ChargeryBMS16Pro) but have not gotten a reply yet. Are the high and low V cutoffs programmable on that BMS you use? I do like that feature on the Chargery.

12 * 300 W (10 fixed rooftop, 2 movable pole mount), Morningstar Tristar MPPT 60, Magnum 4448 PAE, 64 200Ah CALB in 4p16s arrangement with 16 LED Balancers and a Choice BMS300 (It is lousy and I don't recommend but it provides high and low voltage cutoff) -

Yes @Dave the high/low cutoffs are adjustable, see values in attached pdf, the reason I didn't use it as the primary BMS is I didn't like that it needs a solenoid which needs to be powered for a fail safe installation, it also lacks some of the features of the other BMS as it is primarily designed for EV applications. Jason stopped communication as soon as I mentioned what I was using the Chargery for, it's an okay unit for the $80 I spent on it, but as I said I simply wanted a display at the press of a button, rather than connecting via a phone or PC.

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding.

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed