Battery interconnect and NEC code

Options

ctann

Registered Users Posts: 12 ✭✭

Hi all,

I am designing my battery bank, and want to make sure it is NEC code compliant. I will have a single string of 24x2V DC1150-2 batteries, which will be hooked up (eventually) to 4 parallel Magnum MS4448PAE inverters. I will be using a Magnum MPDH panel for the connections, so will have 4x175A breakers, connecting to 4 2/0 cables off to the battery bank. The negative side is easier, as the 4 cables are bused together in the Magnum panel.

I know I will need to come up with a busbar to join the 4 positive cables to my battery bank. However, I am wondering about code-compliant battery inter-connects. I've read a lot of people posting against using busbars as interconnects, but frankly at 700A, I don't see there is any other choice (I really don't want to parallel-cable between batteries). Batteries will be installed in a lockable chest-style outdoors battery enclosure. From an online sizing tool, it looks like 2"x1/8" or 1"x3/8" is the right size (but I of course need to double-check).

So, questions:

- Do bus-bars meet NEC code for battery interconnects?

- Do the bus-bars need to be insulated (shrink-wrap or tape or some such)?

- I am assuming the 4x175A breakers are all I need to be code compliant (battery box to breakers is < 5'), right?

- Anything else NEC code-wise I need to beware of with such a high-current installation?

Note: there is an off-chance I will need to use two banks to get the "cloudy days" autonomy I need. I'll cross that bridge when I come to it, right now it seems that close to 50kWh (25kWh) should cover my needs...

Regards,

Chris.

I am designing my battery bank, and want to make sure it is NEC code compliant. I will have a single string of 24x2V DC1150-2 batteries, which will be hooked up (eventually) to 4 parallel Magnum MS4448PAE inverters. I will be using a Magnum MPDH panel for the connections, so will have 4x175A breakers, connecting to 4 2/0 cables off to the battery bank. The negative side is easier, as the 4 cables are bused together in the Magnum panel.

I know I will need to come up with a busbar to join the 4 positive cables to my battery bank. However, I am wondering about code-compliant battery inter-connects. I've read a lot of people posting against using busbars as interconnects, but frankly at 700A, I don't see there is any other choice (I really don't want to parallel-cable between batteries). Batteries will be installed in a lockable chest-style outdoors battery enclosure. From an online sizing tool, it looks like 2"x1/8" or 1"x3/8" is the right size (but I of course need to double-check).

So, questions:

- Do bus-bars meet NEC code for battery interconnects?

- Do the bus-bars need to be insulated (shrink-wrap or tape or some such)?

- I am assuming the 4x175A breakers are all I need to be code compliant (battery box to breakers is < 5'), right?

- Anything else NEC code-wise I need to beware of with such a high-current installation?

Note: there is an off-chance I will need to use two banks to get the "cloudy days" autonomy I need. I'll cross that bridge when I come to it, right now it seems that close to 50kWh (25kWh) should cover my needs...

Regards,

Chris.

Comments

-

I'm not a code weenie, but it sure looks like I would try to pare down the loads some, you are working with some massive power.

Have you considered fork lift batteries ?

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

With that amount of Amperage you REALLY NEED to protect yourself from an inadvertent short, like ... a very wide space that is physically divided between the + and - buss bars.... and covered after connections being made... SAFETY FIRST!!

KID #51B 4s 140W to 24V 900Ah C&D AGM

CL#29032 FW 2126/ 2073/ 2133 175A E-Panel WBjr, 3 x 4s 140W to 24V 900Ah C&D AGM

Cotek ST1500W 24V Inverter,OmniCharge 3024,

2 x Cisco WRT54GL i/c DD-WRT Rtr & Bridge,

Eu3/2/1000i Gens, 1680W & E-Panel/WBjr to come, CL #647 asleep

West Chilcotin, BC, Canada -

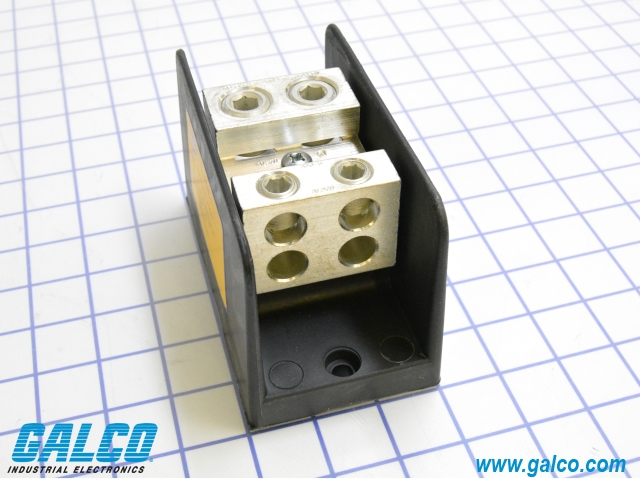

Hi Chris, I think bus bars are fine, but I would look for Power distribution blocks. I saw this new variety at Northern Arizona Wind and Sun, that is insulated and allows up to 250 kcmil, 4 ports, I they don't list the amp rating or if it's UL listed.

https://www.solar-electric.com/4podueninpod1.html?gclid=Cj0KEQjw76jGBRDm1K-X_LnrmuEBEiQA8RXYZwxKs4d7893bypQNQjA-6ohggXcIBCBhlAdHnmwA__waAgpZ8P8HAQ

The old type is UL and have an amperage rating;

This will meet your needs, 4 - 4/0 and a two 500 kcmil on the other side (no need to use both).

http://www.galco.com/buy/Ilsco/PDB-24-500-1

While I don't think it effects you, They do make this style side by side with just the insulator wall. They have changed the NEC rules and now there needs more space/insulation between the blocks. In case you wanted to run the + and - side by side. They do make these with 3 blocks side by side, I don't know enough about the rules to know if you can use the outer 2 in a 3 block.

I may even have a side by side that would work for you in the shed, not that you look to be doing this on the cheap...lol.

Home system 4000 watt (Evergreen) array standing, with 2 Midnite Classic Lites, Midnite E-panel, Magnum MS4024, Prosine 1800(now backup) and Exeltech 1100(former backup...lol), 660 ah 24v Forklift battery(now 10 years old). Off grid for 20 years (if I include 8 months on a bicycle).

- Assorted other systems, pieces and to many panels in the closet to not do more projects. -

The distribution block @Photowhit posted are UL/CSA listed so I would assume they would be rated at least for the current capacity of the largest allowable conductor 340-455 amps for copper in free air at 30°C, depending on cable insulation rating.

At 700A there are not many options other than bus bars, would be a tidy method and heat shrinking would be a good idea, red/black for polarity distinction. As this needs to comply to code, perhaps asking the inspector his/her opinion, would be a prudent thing to do, my thinking is, it would be the preferred method.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

The rating may be for the largest cable, which the linked one is 500 kcmil, I don't know.mcgivor said:The distribution block @Photowhit posted are UL/CSA listed so I would assume they would be rated at least for the current capacity of the largest allowable conductor 340-455 amps for copper in free air at 30°C, depending on cable insulation rating.

At 700A there are not many options other than bus bars, would be a tidy method and heat shrinking would be a good idea, red/black for polarity distinction. As this needs to comply to code, perhaps asking the inspector his/her opinion, would be a prudent thing to do, my thinking is, it would be the preferred method.

It is rated at 760 amps, which should be fine.

Home system 4000 watt (Evergreen) array standing, with 2 Midnite Classic Lites, Midnite E-panel, Magnum MS4024, Prosine 1800(now backup) and Exeltech 1100(former backup...lol), 660 ah 24v Forklift battery(now 10 years old). Off grid for 20 years (if I include 8 months on a bicycle).

- Assorted other systems, pieces and to many panels in the closet to not do more projects. -

Thanks for all the replies. This is for a large offgrid home (eventually two homes), so I don't think that 25kWh of usable reserve is too far off the mark (actually is a little light long-term). Robust and low maintenance are two of my major design goals. Longevity is the third goal, which in my experience usually derives from the first two.

I did think about forklift batteries, but where the batteries will be installed does not have fantastic access (i.e. no chance to get a forklift in to that spot). Individual cells means a lot of heavy lifting, but do-able for two people (and hopefully when they need replacing, battery technology will have caught up a bit and I'll just be able to throw in a few next-gen PowerWalls... )

@Photowhit , I'm not sure I see how to use terminal blocks for this. Are you suggesting "Battery -> Cable -> Terminal block -> cable -> battery"? that still needs parallel cables for this sort of amperage (eg a pair of MCM500 cables to each battery).

I am surprised that there is not an off-the-shelf solution for this. The battery manufacturers sell these 2V cells that will put out 600+ amps for an hour, it seems an interconnect solution would be an obvious requirement, but several times scouring the web has left me where I started. I remember from my scrub through the NEC that the battery interconnects must handle the same current as the maximum battery output, but don't remember any other requirements. Maybe I will go digging again to try and find the exact reference.

Looking at photos of forklift batteries, I do see the interconnects are just what I want - busbars covered with a fitted plastic shroud. To me that is even better than cables, as every cable installation I see skips the "boot" step and leaves the terminal exposed. However, I have so far not been able to find a source for just the busbars themselves. Maybe this is the direction I need to dig...

My other option is to go with parallel strings, and protect each string with a lower OCPD. Still, even two strings capped at 350A requires MCM350 cable. Magnum actually shows 4 parallel strings in their connection diagram - all my research has pointed to avoiding parallel strings, and especially not going over three. Magnum shows it without extra OCPD (i.e. the parallel connection is battery-to-battery), but I am still having a hard time seeing how that could be code compliant, I would think each string must be OCPD protected based on the max ampacity of the battery interconnect...

Regards,

Chris.

-

i'd put the owners on a energy diet, Just saw my folks electric bill. Their lowest usage is about 6x my highest usage, but they use air con in the summer & heat pump in the winter Yow !

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

Power distribution panels From Schneider, Outback, and Midnite might give you some idea of what the industry uses. Look at the 3 phase systems or microgrid applications. Look at the 6848XW+ in a dual inverter App or the Radian dual.

I agree that you should be able to get along on 12KWH or less of overnight usage. Most of mine do with a mini-split and propane or wood in the depth of winter. The key is too be able to quickly charge and still supply the loads 95% (or more) of the year. Lot's of solar from sunrise to sunset or, the iron beast."we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Hi again all,

The comments on reducing loads are well taken, but for this particular issue, the battery bank reserve capacity is not what is important. What is important here is the peak load - and indeed, theoretical peak load in order to be NEC compliant. So to support 4x4.4kW magnums, the max current draw is 4x175A - 700A, and with a single string battery bank, the interconnects must also be able to support that load. I may find out I can get away with less than 4 parallel inverters, but in case I find I need to increase peak load capacity, I don't want to have to re-wire the battery bank.

I did come across braided connectors. That seems to be a little more robust than solid copper bus bars. Uninsulated though, and pretty steep @ $90 a piece https://stormpowercomponents.com/products/spcb3e12

The special-order insulated flexible busbars would seem like the perfect solution, although custom ordered

https://stormpowercomponents.com/shop-our-stock/flexible-electrical-connectors/flexible-insulated-busbar-eriflex

I want to make sure that whatever I pick is 100% safe, and 100% code compliant, and I would like to get the design right before I submit the plans...

Regards,

Chris.

ps - for reference, this is intended to be a "net-zero" application, so all electric - no propane for things like cooking, heating and DHW. With an induction cook-top, electric oven, electric DHW, electric dryer, catering for a high peak load is also important. The oven/cooktop comes in around 10kW peak, and the DHW/heating at 5.5kW, and a dryer at 5kW, that is a 20kW load. While I could try to implement scheduling, I don't want to be forced into that. Certainly load-balancing is important, but I don't want a non solar-savy guest to trip breakers by running the dryer when they shouldn't...

-

Solar Neophyte. Fool, Money. Parted.ctann said:......

ps - for reference, this is intended to be a "net-zero" application, so all electric - no propane for things like cooking, heating and DHW. With an induction cook-top, electric oven, electric DHW, electric dryer, catering for a high peak load is also important. The oven/cooktop comes in around 10kW peak, and the DHW/heating at 5.5kW, and a dryer at 5kW, that is a 20kW load. While I could try to implement scheduling, I don't want to be forced into that. Certainly load-balancing is important, but I don't want a non solar-savy guest to trip breakers by running the dryer when they shouldn't...

I'll advise you to wire/plumb the house for gas & electric appliances. That gives you a fall back. Where I am, I get weeks of cloudy winter days. All electric will be murder under those conditions. Also gives options for future owners, to use what they want. Building all electric without robust, dual generator backup (the generator never fails on the long sunny days of summer, only in cloudy weeks in winter.)

Just my 5 cents of advice

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

Solar neophyte, yes - and why I am on here asking questions. Fool, no - doing my due diligence and crunching my numbers. The DHW/heating alone makes net-zero very challenging, and I am fully aware that the final design may not work out. Fool is building it and then asking the questions... or building it and *then* having to re-wire everything because of not adequately planning for the peak loads...mike95490 said:Solar Neophyte. Fool, Money. Parted.

Anyway, propane or electric, I still want to design my system to be extensible to the full quad-magnum setup... so - 700A battery interconnects anyone?

Chris.

-

The link is for a company that makes custom bus bars, braided straps interconnects etcetera , insulated or not.

https://stormpowercomponents.com/custom-components/fabricated-parts/battery-posts

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

OK, I'm confused, I hope that I am the only one. String of 24 L-16 batteries (48 VDC) and 4 Magnum MS4448 inverters, and 4 175 amp breakers with 4 2/O cables from the batteries to the breakers, from the breakers to the inverters, where does the 700 Amp buss bar come into play?

Lets forget about the over design.

Rancher

-

Hi cow_rancher

Between the individual 2V cells. For a single string battery setup, those 4 x 2/0 cables to the battery bank need to be bused together, and then connected to the first cell in the battery bank. That means that cell can pull 4 x 175A = 700A, and thus all of the interconnects between cells need to be designed to the same spec. I don't want to over-design, but I do want to be both code compliant, and safe.cow_rancher said:OK, I'm confused, I hope that I am the only one. String of 24 L-16 batteries (48 VDC) and 4 Magnum MS4448 inverters, and 4 175 amp breakers with 4 2/O cables from the batteries to the breakers, from the breakers to the inverters, where does the 700 Amp buss bar come into play?

Magnum shows 4 parallel strings of batteries in their MP manual for a quad inverter setup. With the addition of appropriate fusing that could be made code-compliant (using simple 2/0 interconnects), but everything I have learned suggests that parallel strings, especially more than 3, should be avoided wherever possible.

Chris.

Categories

- All Categories

- 228 Forum & Website

- 136 Solar Forum News and Announcements

- 1.3K Solar News, Reviews, & Product Announcements

- 198 Solar Information links & sources, event announcements

- 895 Solar Product Reviews & Opinions

- 255 Solar Skeptics, Hype, & Scams Corner

- 22.4K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.5K Off Grid Solar & Battery Systems

- 428 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 652 Solar Water Pumping

- 815 Wind Power Generation

- 624 Energy Use & Conservation

- 618 Discussion Forums/Café

- 311 In the Weeds--Member's Choice

- 75 Construction

- 124 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed