2 AWG on wiring

Renato

Registered Users Posts: 2 ✭

Hello,

My system is comprised of the following:

Controller RNG-CTRL-ADV30-LI + Solar panel RNG-160DB-H + Battery RNG-BATT-AGM12-100

My system is comprised of the following:

Controller RNG-CTRL-ADV30-LI + Solar panel RNG-160DB-H + Battery RNG-BATT-AGM12-100

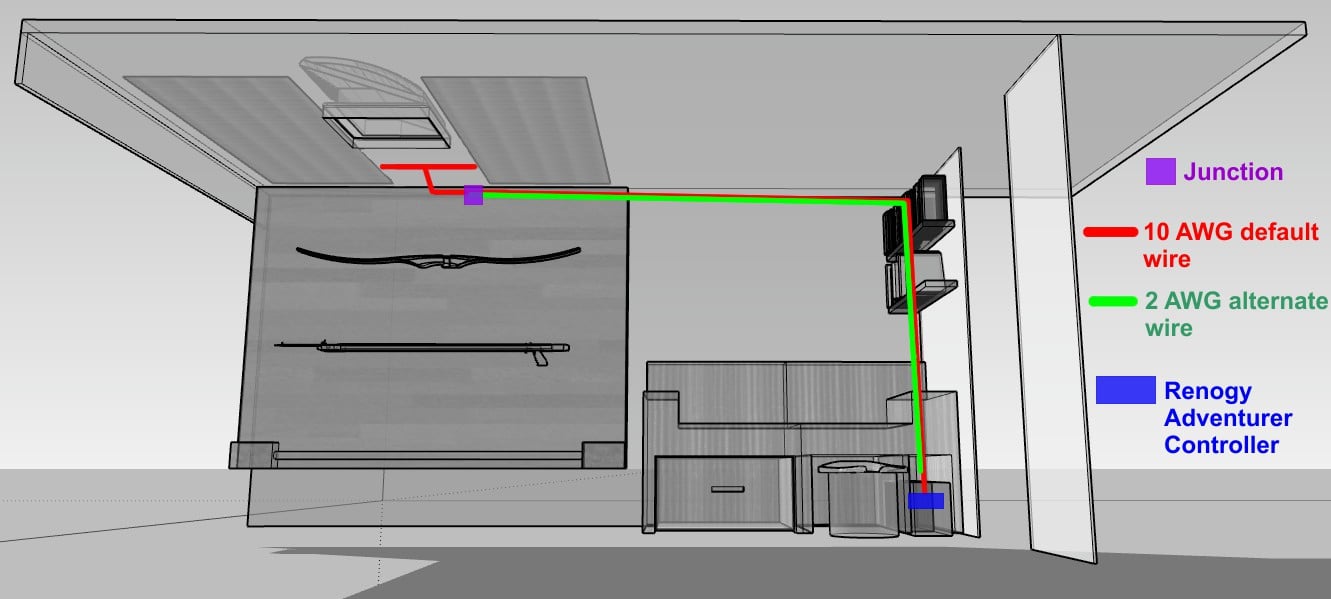

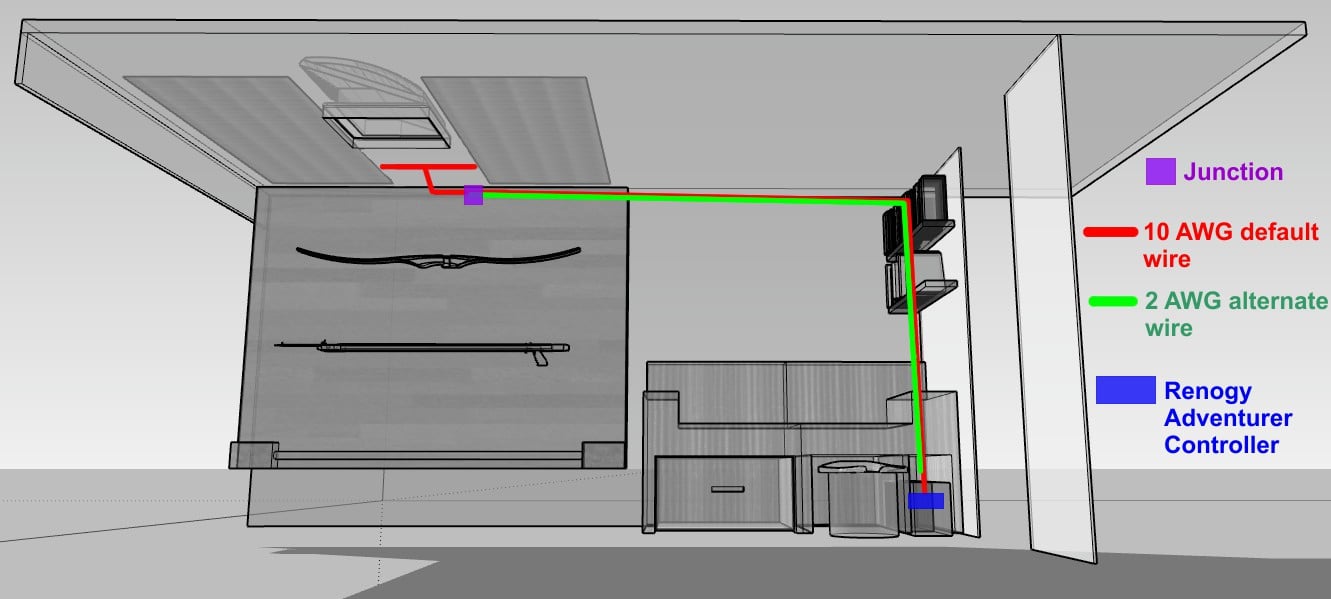

I know we should install our solar panel as close to the controller as possible, in my case I have a distance of 13 feet (~4 meters) between the junction and the controller. I have plenty of 2 AWG cable laying on my garage. Would it be any good to use it as illustrated? Or should I just use 10 AWG?

I would still have to use the 10 AWG from the junction to the panels and to connect the controller.

Thank you.

Comments

-

Welcome to the forum

Whenever there is the opportunity to use larger gauge without incurring additional expense, do so if it physically possible, this is especially important with 12V systems.1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

Even though there will be 10AWG on both ends of the 2AWG?

There is no additional expense but it will be a PITA to run the 2AWG on the curves and corners.

I understand that in theory the larger diameter would produce less heat but will it really make any difference on the drop voltage since both ends have 10AWG? -

Generally, the solar panel to charge controller is a longer distance, so you want to design for (typically) 1% to 3% voltage drop. Vmp-array (panel) of ~18 volts would be 0.2 to 0.5 volt drop. So what is the solar panel Vmp/Imp rating, and what is the distance from the array to the controller.

The more "critical" issue is having small voltage drop from the charge controller to the battery bus. For a 12 volt bank, you probably are looking at 0.05 to 0.1 volt drop maximum. Not because you are trying to "not lose/waste energy", but because you want the charge controller to "accurately measure" the battery voltage during charging. To large of voltage drop will reduce charging current (i.e., controller measures 14.4 volts for charging AGM battery, and a 0.5 volt drop, the battery would actually be charging at 13.9 volts--Dramatically slowing down the charging process. Usually, you are looking at a pretty short distance from the charge controller to the battery bank (a few feet). What is your Controller to Bank wiring distance?

I cannot tell, but it looks like your charge controller is planned for near the ceiling and the battery on the floor? Another issue is that charge controller have an internal temperature sensor (some have wired remote temperature sensor options too), and you want the controller and the battery bank to be at roughly the same temperature. You don't want the controller "hot" near the ceiling, and the battery on a cold floor--The charge controller would "adjust" the charging voltage down by another few 0.1's of a volt--And slow your charging too.

Lastly, you want good air circulation around the charge controller... Make sure that there is good airflow across the controller--And it does not get hot air trapped around the controller (enclosed cabinet, controller tucked under a shelf, next to ceiling).

Your other question--Yes, you can run 5' of 10 AWG cable from the panel, then 30' of 2 AWG, and another 3 feet of 10 AWG... That will reduce the overall voltage drop. And the "circuit" would still have a maximum current rating based the 10 AWG segments.

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Making the jump from 10ga to 2ga is way too much overkill (and I'm Mr Overkill) 8ga would be fine, 6ga would be overkill. Anything larger for your shortish run is wasteful.

Save the 2ga for the run from controller to battery, although 6ga would be more than enough

In my opinion.Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister ,

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed