Setting that epever up for lithium, what to do with boost/absorb and float voltages.

unexpected

Registered Users Posts: 30 ✭✭

Since I'm getting 2 nissan G1 lithium packs, need some help setting up the tracer AN. I've deduced the following:

Each battery is a 2s2p, 2 of them should give me ~16v and still work with a non 24v+ voc panel.

Empty voltage 2.5v per cell

Nominal 3.75v per cell

Max 4.15v per cell

Knee 3.2v per cell (from users of large banks on youtube)

Operation temperature range -25 ~ 60 ℃ (which i will just program)

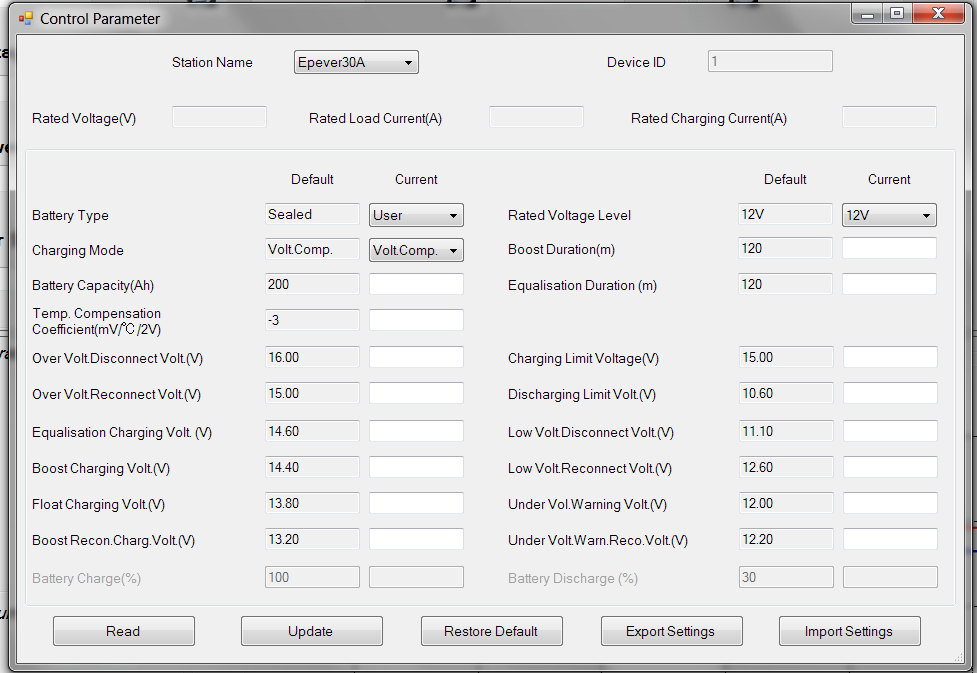

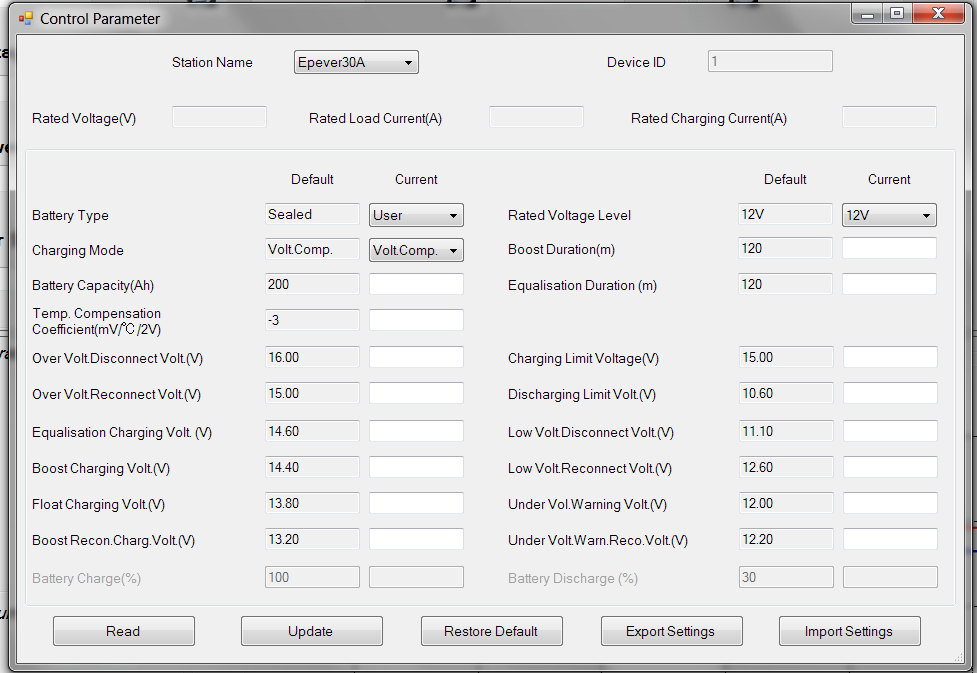

So now for the epever, less straight forward. It claims to support lithium but these settings can only be set up from the user parameters in the PC software. I don't know if the "lithium" parameter page settings all even work or what oilengine control is.

Over Voltage Disconnect: 16.6 (4.15)

Over voltage reconnect 16.2 (4.05)

Equalization: 16.4v (4.1) time 0,disabled

Boost Voltage: 16.4v (4.1) time 0, disabled

Float Voltage: 15.6v (3.9) ??

Boost Reconnect 15.2v (3.8) ??

Charge limit: 16.4v (4.1)

Discharge Limit 12v (3.0)

Low Voltage Disconnect: 12.8v (3.2)

Low Voltage Reconnect 14v (3.5)

Under voltage warning: 13.2v (3.3)

Under volt end 14v (3.5)

That's what I've come up with to get an SOC in the low 90s and discharge to about the knee voltage where current output will drop anyway.

What I don't know is if the float voltage should be lower/higher and if I should be completely disabling the boost/absorb stage. With the time at 0 the controller will charge in bulk to 16.4 and then drop into float, which is hopefully low enough to not stress the cells but still allow the panel to directly drive loads.

Not sure what voltage will bring back the bulk charge unfortunately or if that boost should act as a buffer in between.

Thoughts?

The pages:

Each battery is a 2s2p, 2 of them should give me ~16v and still work with a non 24v+ voc panel.

Empty voltage 2.5v per cell

Nominal 3.75v per cell

Max 4.15v per cell

Knee 3.2v per cell (from users of large banks on youtube)

Operation temperature range -25 ~ 60 ℃ (which i will just program)

So now for the epever, less straight forward. It claims to support lithium but these settings can only be set up from the user parameters in the PC software. I don't know if the "lithium" parameter page settings all even work or what oilengine control is.

Over Voltage Disconnect: 16.6 (4.15)

Over voltage reconnect 16.2 (4.05)

Equalization: 16.4v (4.1) time 0,disabled

Boost Voltage: 16.4v (4.1) time 0, disabled

Float Voltage: 15.6v (3.9) ??

Boost Reconnect 15.2v (3.8) ??

Charge limit: 16.4v (4.1)

Discharge Limit 12v (3.0)

Low Voltage Disconnect: 12.8v (3.2)

Low Voltage Reconnect 14v (3.5)

Under voltage warning: 13.2v (3.3)

Under volt end 14v (3.5)

That's what I've come up with to get an SOC in the low 90s and discharge to about the knee voltage where current output will drop anyway.

What I don't know is if the float voltage should be lower/higher and if I should be completely disabling the boost/absorb stage. With the time at 0 the controller will charge in bulk to 16.4 and then drop into float, which is hopefully low enough to not stress the cells but still allow the panel to directly drive loads.

Not sure what voltage will bring back the bulk charge unfortunately or if that boost should act as a buffer in between.

Thoughts?

The pages:

Tagged:

Comments

-

The lack of response to your question and other comments around the web and in the tracer hand book i.e. ' The voltage shall be determined by the installation engineer' make me think the holy lithium batteries may be the devil in disguise !!!

-

Lithium batteries are very picky about charging voltage (and you don't exceed max current limits).

The more stable Li Ion chemistry is the Li Iron Phosphate (LiFePO4) battery chemistry--Which typically has a max charging voltage of ~3.7 volts. These are the type of batteries typically used in an off grid home/solar installation because they are much safer (and folks will run them without BMS--Battery Monitor System).

It sounds like you have non-LiFePO4 batteries... These are much higher power density and can supply higher current. But they can be much more sensitive to over/under voltage issues causing a fire--And much less likely you would run these sorts of packs without a BMS.

HOWEVER, I am not a battery engineer--And I do not follow Li Ion battery forums/etc... Perhaps some folks here can give you their experiences and recommendations.

These batteries can cause series issues with safety--And I really do not feel competent to give you recommendations on their use--At least without a battery manual.

I would confirm are you running from -25C (minus 25C) to +60C? Most Li Ion batteries generally should not be charged when you get to or below freezing (0C).

Most Li Ion seem to use Zero temperature compensation...

And I am not sure what your screen shot is. Before you program (general settings and options) or after you have set the programming (3 cells in series vs the 4 you are using, etc.).

The controller has an impressive amount of settings/options for your battery bank. The problem of running without a BMS is you cannot tell the cell to cell voltage levels (BMS typically monitors each cell/parallel group of cells).

I would suggest that you install the battery outside the living area of your home (separate shed would be good). And you take fire precautions (dry wall/plaster/brick/non-flammable materials around the battery bank).

Li Ion batteries do scare me a little bit--EVen though we all have lots of them in our computers, electric tools, and even flashlights these days...

And using a car battery pack without the internal BMS...

https://hackaday.com/2016/06/16/reverse-engineering-a-nissan-leaf-battery-pack/

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

I wonder how accurate the voltage measurement is in the controller? A tenth of a volt is probably "close enough" for lead acid.

Seems to me if the actual vs controller measured voltage could be off by a tenth or so, and individual cells will vary from the bank average (absent balancers), there's a good chance some cells could potentially get into a badly over/undercharged condition.

Maybe not so likely with only 8 cells vs many times that in a Leaf bank?Off-grid.

Main system ~4kw panels into 2xMNClassic150 370ah 48v bank 2xOutback 3548 inverter 120v + 240v autotransformer

Night system ~1kw panels into 1xMNClassic150 700ah 12v bank morningstar 300w inverter -

Only 2 leaf modules. So a fraction of that giant pack in the car. These are LiNiMn; relatively safe chemistry, not the explody kind. I saw someone try to destroy a pouch, no fire like a regular battery. They have to survive auto crashes. Biggest danger is puffing them and losing $130 of battery.

It will have individual cell monitoring and a balancer but so far counting on the epever to stop charging, which may or may not be a problem. I will be checking with a good DMM too and seeing how well the battery is matching, on the lead acid the voltage is the same or lower by that .1, lol. So its off in the "right" direction. With the error I would have an ~80-40 SOC which would give me really good cycles.

I get being scared by LiIon cells, they store lots of energy. I've destroyed some 18650s on purpose and they get really hot; making them roman candle isn't the easiest thing, however, even though that is the "worst" chemistry.

-

Get yourself a BMS, lithium is all about cell voltage, not bank voltage, if you think you could react to cell voltage change faster than a BMS you would be horribly wrong. Operating within the safe zone is one thing, knowing the cells are ballanced is another, did you ballance the cells prior to use?

Im not being negative, just trying to help, this link http://liionbms.com/php/index.php has a wealth of information albeit related to EV applications which is very different to solar, but there is a BMS search tool to assist in selection. What voltage settings are you intending to, or are currently using?1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

What type of battery is your "LiNiMn" ? That is only a partial description of the chemistry.is it Lithium ion nickel manganese cobalt oxide (NMC) ?

Li-cobalt

LiCoO2 (LCO)Li-manganese

LiMn2O4 (LMO)Li-phosphate

LiFePO4 (LFP)NMC

LiNiMnCoO2There are some really good writeups here about Li batteries

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

Mike, it is LMO and known for degrading in hot US locations because it is air cooled on the Leaf. I would urge the OP to read about the failure modes and be able to test for bad cells in used batteries. Good Luck!"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Its a mixed type LMO/NMC. Kind of its own thing being an EV battery. Voltages in 1st post, going to be a 16v system.

Bottom balancing is happening today but don't think these are prone to getting unbalanced from what I've read. They are already within .1 of each other.

I'm not even done making the bus bars so nowhere near installed.

-

Yes, in general, Li Ion batteries are pretty well matched and don't have very much self discharge current--So, they do not tend to get "out of balance" very quickly (months at least, possibly years of "good balance").

Of course, this depends on how much you "push" the charge and discharge voltages... The closer you get to Max/Min bank voltages, the more critical a single cell that is "high or low" compared to the other cells, that that cell can be damaged. For example if your cell is rated at 4.2 volts @ 100% and you only charge to 4.0 volts @ 90% (made up numbers), your bank will last longer and now (for 4x cells) you have 4*0.2 or 0.8 volts of "slop" between the top bank voltage and "overcharging", and each cell has a 0.2 volt "headroom" from being "overcharged" and damage... And if you do your monthly or semi-annual balance check, you will see that 4.15 volt "high cell" and get the bank rebalanced... If you charge to 4.15 volts, now you only have 0.05 volts of headroom to catch with your balance check before damage.

As I understand, "bottom balance" is to ensure that all cells reach "zero capacity" at the same time (and voltage)--And is used for Electric Vehicles--They want to ensure cells/banks are not damaged if "run dry".

Top Balance is typically used for Solar Power systems to ensure that each cell/bank is charged to its maximum capacity. And you should be reaching your 80-100% SoC much more often than your 20% to 0% state of charge during normal home operation.

And most folks will run like 90%/10% or 80%/20% of capacity... Allowing headroom for out of balance cells (if present). Also, even Li Ion batteries typically have shorter cycle and aging life if run close or at 100%/0% state of charge.

I try not to be too repetitive in giving warnings... I don't know your skill level and intentions. But I do want "you" (i.e., all of our readers) to be cognizant about the primary and secondary issues when dealing with power systems.

Rules of thumbs and NEC (national electric codes) keep us 95% "safe". When folks want/need to push the 5% boundary, then understanding the multitude of underlying issues as to why the thumbs and codes were created in the first place becomes much more important.

-Bill "I am not a battery engineer" B.

Near San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

maybe 4.0 is better for more headroom. I think the epever is off by .1 anyway so I will really be at 4.0. Will be watching the balance board while I do this and see what happens. Probably not much charging is happening today anyway but at least I'll get it set up. The cells are less than .010 off from each other at 3.2v

-

The problem with solar charge controllers is that they do not limit current as voltage increases with lithium batteries, it's maximum available current until 100%.or beyond to destruction. Limiting charging voltage to 4.000 Vpc is probably a good starting point but if the cells are bottom ballanced they won't be top ballenced, so there could be one cell which overcharges, for example 3 cells at 3.950V and one 4.200V. When the setpoint voltage nears the knee things happen very rapidly, with a charger dedicated to the cell type is used, the current will taper down to a very small value to allow cell voltages to align slowly, this is also what a BMS will do, if any single cell runs away it will reduce the current to prevent cell runaway.

The choice of wether to top or bottom ballance should be made on where the battery needs the most protection from cell imbalance, EV typically use bottom, solar typically top, because EV is typically operate at high discharge currents. There are differing schools of thought on that subject, with solar the inverter would be programmed to shut down at a safe voltage to prevent over discharge, most inverters are intended for lead acid batteries which operate at much lower voltage thresholds, so that needs to be considered, some may not even operate over 15V.

My suggestion is don't rush into this project without considering all potential pitfalls, and remember with lithium cells, milivolts are very important. Below shows my system as it approaches full charge the 16 mV is the differential between highest and lowest cell voltage, the cells were top ballenced.

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

My cells are:

1: 3.350v

2: 3.351v

3: 3.346v

4: 3.345v

That's pretty good for at the bottom. Similar to yours. No sun so no charging

When they get towards the top I will balance again. I've looked at some cutoff boards and more LVDs since the one I got goes off way too quick under load and does a big voltage drop. For such simple stuff you'd think there would be cheap reliable boards but no dice yet.

I tested my inverter at 15v without issue but 16v is yet to be seen, hopefully it works. I could use a step-up board and see if it will start with no load there. Did so and it started fine at 16.5v

-

I found this site: https://www.powerstream.com/lithium-ion-charge-voltage.htm and it looks like 4.0-4.05 looks like a good place to be.

Then if I float at 3.9 the battery should never charge unless depleted below those values.

I attached my profile. It will probably need some tweaks. That last bit of voltage is taking a bit to get into the cell. Balance is good right now.

Tomorrow I get to see what happens when I run loads while the battery is charged up.

-

You have to find the information from the exact battery/cell manufacturer... There are lots of different li ion chemistries---And what is safe and sane for one chemistry can be a huge problem for another.

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

That's going to be really near impossible. They are recovered cells from an EV battery. Nissan started up their own plant for these. Best I got it is:

-

unexpected said:My cells are:

1: 3.350v

2: 3.351v

3: 3.346v

4: 3.345v

That's pretty good for at the bottom. Similar to yours. No sun so no charging

When they get towards the top I will balance again. I've looked at some cutoff boards and more LVDs since the one I got goes off way too quick under load and does a big voltage drop. For such simple stuff you'd think there would be cheap reliable boards but no dice yet.

I tested my inverter at 15v without issue but 16v is yet to be seen, hopefully it works. I could use a step-up board and see if it will start with no load there. Did so and it started fine at 16.5v

The purpose of the image was to show the mV spread as the battery approaches fully charged, the cells are lifepo4 so the maximum cell voltage they will reach is ~ 3.420V, the 100% fully charged voltage is 3.600V. The values are also under charging conditions, at rest the differential would be much closer, your cells would be at a higher voltage in the same charging conditions, so a comparison can't really be made.

Being initially bottom ballanced the voltage differential would increase as they approach 4.xxx V, if you ballance them again when they get towards the top, you will then top ballance, you can only choose one, top or bottom, not both. Both methods are very sensitive to cascading voltage in bottom ballancing or runaway voltage when top ballancing, having a means to control this in the form of electronics is is essential, IMHO, hense the suggestion of using a BMS or a dedicated single cell charger for top ballancing, should you choose to go that route.

There are many BMS's available which can be custom programed, you would however have to know exactly what you're doing, or as I did was to provide all information, battery specifications, maximum charge/discharge currents, method of charging, battery capacity and voltage to a BMS manufacturer, this information was forwarded to their engineering department and a BMS was recommended.

Since your cells cells are unique to some degree, as well as not being specifically intended for the application proposed , my suggestion is to gather as much information as possible and present it to a BMS manufacturer to see what they may suggest, it is likely they may fall under the umbrella of a similar chemistry, but that is purely speculation.

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

They are approaching near the top right now and the balance got even closer. I get the feeling a custom BMS would cost more than I've spent on the entire system.

-

Ok, so I got it to stop charging in "float" mode. No current passes to the battery. Unfortunately the charge controller lets the load come from the battery instead of powering the load with solar, which is bonkers.

So I'll raise float some more like this guy:

https://www.youtube.com/watch?v=ofmXkwYEbvo

https://www.youtube.com/watch?v=ofmXkwYEbvo

-

The BMS I ordered with the specifications provided for my particular application was ~$100, not including shipping, taxes and duties.unexpected said:They are approaching near the top right now and the balance got even closer. I get the feeling a custom BMS would cost more than I've spent on the entire system.

Watched the video, there was no indication wether there is, or is not a BMS connected. Based on the constant current then constant voltage or Boost transition, which I assume is absorption, there would be little benifit in my opinion to doing this, the only reason to do this for 120 minutes, as far as I can tell would be to allow top ballancing which would require a voltage at the maximum allowing a BMS to reduce current to charge individual cells, or to cut current and bleed off the higher ones. Normally a voltage which would be in the mid 90% region is chosen, then a short absorption ~5 minutes before float, this is to satisfy the controllers needs, which are really designed for lead acid batteries.unexpected said:Ok, so I got it to stop charging in "float" mode. No current passes to the battery. Unfortunately the charge controller lets the load come from the battery instead of powering the load with solar, which is bonkers.

So I'll raise float some more like this guy:

https://www.youtube.com/watch?v=ofmXkwYEbvo

https://www.youtube.com/watch?v=ofmXkwYEbvo

Without a BMS the voltage could runaway on a single cell or two, due to their inherent low resistance, this happens extremely fast, even if one had four accurate DVM's connected to each cell, it's unlikely the time taken to respond, as a human, would be sufficient.

The BMS that I have has separate charging / dischargeing ports which allows current to bypass the battery, allowing the PV to support loads without drawing from the battery, until such time the PV cannot provide support, then it blends the two together.

Should the choice be to operate without a BMS, be very careful with the settings, making sure the equipment has tight control, something the Tracer, Epever or whatever it is branded as, is not renowned for, based on reports, not personal experience.

1500W, 6× Schutten 250W Poly panels , Schneider MPPT 60 150 CC, Schneider SW 2524 inverter, 400Ah LFP 24V nominal battery with Battery Bodyguard BMS

Second system 1890W 3 × 300W No name brand poly, 3×330 Sunsolar Poly panels, Morningstar TS 60 PWM controller, no name 2000W inverter 400Ah LFP 24V nominal battery with Daly BMS, used for water pumping and day time air conditioning.

5Kw Yanmar clone single cylinder air cooled diesel generator for rare emergency charging and welding. -

You need to be aware of the limits of your BMS. Most are designed to work with a paired charger, so it can throttle the charger back as needed.Many of the BMS with bleeder boards, can only bleed or bypass 1-5 amps. If your charger is putting out 9 amps, and only 4 are getting bypassed, you are still charging your full cell with 5 amps - way too much.Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

I am nowhere near runaway. I'm actually going with nasa 3.92v as a top now to prolong those more limited cycles and to keep them from sitting full. It takes a long time to push enough amps into these batteries to get voltage to climb. Think about it, I have 95A discharge and at least 65A charge capable batteries and my system can only generate 7-8A on a good day. I would have to purposefully fully charge the battery one day and then raise the voltage limits in the charge controller to even hope of puffing them. If I double my wattage as I hope to this year I will only reach .3C. And this is the summer, I have 6 hours of shine, in the colder months it will take like 2 days to recharge.

Btw, I'm using 10 minutes for boost not 120 like that guy. Funnier still, I am trying to go down to that 3.92 from 4.028 and having trouble doing it with my normal use all night. Will have to burn off the excess with a fan or light. Pretty decent batteries.

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed