Building a pack of Lithium Iron-Phosphate cells. Need help with balance theory/charging.

hanslanda

Registered Users Posts: 10 ✭✭

Hello gents, new to the forum, been searching for a place to find some smarter individuals on this matter.

I'll start here. I'm building a home PV system. Iv'e made my own solar panels, and since grid tie is very difficult thanks to WE energies, i'm forced to use a battery storage system. Iv'e looked all around at different types of batteries and landed on LifePO4. They are safe, have a high energy density, can discharge pretty deep, i read 80%. Also the cycle life should be a lot better than LA. Specifics on goals below.

So here it is, i have 160 3.2v 5500mAh lifePO4 cylindrical cells for a grand total of around 2.8kWh of lithium cell. Not bad for $300. My goals are to create a pack, power a 24/7 draw, whilst charging the pack on a 6 hour cycle through the day with the solar. Questions on solar i can pass along to my solar buddies, what i really need help with is the charging system/battery management system, and the overall design of the pack.

Battery ????'s

---------------------------

1)With 160 cells... do I want to parallel as many as I can, and series those parallel lines to achieve my desired voltage?

i.e. Wire 4 rows of 40 parallel cells to achieve 3.2v@ 220 amps, and then series those 4 chains to attain 12.8v @ 220amps?

2) Choosing a voltage. Since i make my own panels.... voltage is not really any special requirement. I don't need a 12.8v system. It could be a 24v or 48v system. I would assume higher voltages are just better for power transmission... but the transmission distance to my AC inverter is only going to be a few feet anyways. Although using life batteries... I can see finding a charge controller that can balance charge 16 cells might be tricky. More or less i need help verifying my thought process on this.

3)Balance charging

Is it necessary with LifePO4? I see some say its absolutely critical... and others who say Life can balance itself much like Lead acid due to its larger than Lipo overcharge tolerance.

4)Balance charging with MPPT. Do MPPT chargers have this ability? Would it be desirable? Otherwise on the charging front i see hobby chargers work very well. Its just a hobby charger wouldn't work with a solar application. I need some form of MPPT that knows how many cells i have much like a hobby charger, and with the abilitiy to balance those cells.

5)BMS iv'e heard good and bad things about BMS's. Some have fried and destroyed packs. Others have prolonged battery life to 5 years. My question here is; would the answer to my solution be to run a standard 'off the shelf' MPPT to a BMS that manages the cells? I feel that's where i'm headed.

6)BMS/MPPT charger ratings.

When i see a battery management system with an amperage rating, is that rating intended to be above the value of the battery? Or is it more or less the max discharge/charge rate? Same question on MPPT's. I assume the latter and more specifically it would pertain to the max charge rate of the battery or the max drain rate, which my load will depend on as well.

That's all i can think of for now! Any help super appreciated guys!

I'll start here. I'm building a home PV system. Iv'e made my own solar panels, and since grid tie is very difficult thanks to WE energies, i'm forced to use a battery storage system. Iv'e looked all around at different types of batteries and landed on LifePO4. They are safe, have a high energy density, can discharge pretty deep, i read 80%. Also the cycle life should be a lot better than LA. Specifics on goals below.

So here it is, i have 160 3.2v 5500mAh lifePO4 cylindrical cells for a grand total of around 2.8kWh of lithium cell. Not bad for $300. My goals are to create a pack, power a 24/7 draw, whilst charging the pack on a 6 hour cycle through the day with the solar. Questions on solar i can pass along to my solar buddies, what i really need help with is the charging system/battery management system, and the overall design of the pack.

Battery ????'s

---------------------------

1)With 160 cells... do I want to parallel as many as I can, and series those parallel lines to achieve my desired voltage?

i.e. Wire 4 rows of 40 parallel cells to achieve 3.2v@ 220 amps, and then series those 4 chains to attain 12.8v @ 220amps?

2) Choosing a voltage. Since i make my own panels.... voltage is not really any special requirement. I don't need a 12.8v system. It could be a 24v or 48v system. I would assume higher voltages are just better for power transmission... but the transmission distance to my AC inverter is only going to be a few feet anyways. Although using life batteries... I can see finding a charge controller that can balance charge 16 cells might be tricky. More or less i need help verifying my thought process on this.

3)Balance charging

Is it necessary with LifePO4? I see some say its absolutely critical... and others who say Life can balance itself much like Lead acid due to its larger than Lipo overcharge tolerance.

4)Balance charging with MPPT. Do MPPT chargers have this ability? Would it be desirable? Otherwise on the charging front i see hobby chargers work very well. Its just a hobby charger wouldn't work with a solar application. I need some form of MPPT that knows how many cells i have much like a hobby charger, and with the abilitiy to balance those cells.

5)BMS iv'e heard good and bad things about BMS's. Some have fried and destroyed packs. Others have prolonged battery life to 5 years. My question here is; would the answer to my solution be to run a standard 'off the shelf' MPPT to a BMS that manages the cells? I feel that's where i'm headed.

6)BMS/MPPT charger ratings.

When i see a battery management system with an amperage rating, is that rating intended to be above the value of the battery? Or is it more or less the max discharge/charge rate? Same question on MPPT's. I assume the latter and more specifically it would pertain to the max charge rate of the battery or the max drain rate, which my load will depend on as well.

That's all i can think of for now! Any help super appreciated guys!

Comments

-

Battery University has some information on this subject ...

http://batteryuniversity.com/learn/article/bu_803a_cell_mismatch_balancing

Do not charge above the mfr specified max voltage

Do not discharge below the mfr specified min voltage

Follow the manufacturers specifications for charging and discharging.

-

Let's just say you actually did connect 40 cells in parallel ...

Then what is going to happen when one cell shorts out to nearly zero ohms? -

Iv'e spent the last 36 hours of my life on battery universe haha. I do RC right now and play with 3s lipo but nothing of this amperage.

The caution is why we balance charge lipo's. But lipo's balance a series set of cells not parallel cells. I plan to balance the series rows with a bms directly or through the charger.

Honestly i'm not entirely sure what the result would be wired in parallel on a complete cell failure. Either drain power from the other cells to try to bring up a dead cell that ultimately blows up (doesn't happen with lifepo4 from what iv'e read?). I always thought a cell failure in series was more dangerous. -

-

there are so good discussions on this forum on LiFePo4 and others, one particularly long one I consider a MUST read about LI batteries... http://forum.solar-electric.com/discussion/comment/365097#Comment_365097

KID #51B 4s 140W to 24V 900Ah C&D AGM

CL#29032 FW 2126/ 2073/ 2133 175A E-Panel WBjr, 3 x 4s 140W to 24V 900Ah C&D AGM

Cotek ST1500W 24V Inverter,OmniCharge 3024,

2 x Cisco WRT54GL i/c DD-WRT Rtr & Bridge,

Eu3/2/1000i Gens, 1680W & E-Panel/WBjr to come, CL #647 asleep

West Chilcotin, BC, Canada -

Please consider the $300 you spent, as your education. Trying to cobble 160 cells together is going to be a nightmare, and a timebomb. It's over 300 electrical connections that need to remain in excellent condition for 5 years of heat and cool cycles.

3Kw does not seem much to be able to run a house and have any reserve.

I had a large pack of well monitored NiCad's ignite when one went bad.

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

Hanslada - a few problems:

Forget the chemistry right now - this is the "ready, fire, aim" concept, which we don't follow here. That is, just cobbling stuff together, and throwing it at the wall to see what sticks.

Before you even begin, you have to know what your *actual* daily power needs are upfront. In addition, you need to know your solar-insolation hours, (which are vastly different than just sunrise-to-sunset hours), based on your geographical location and calculated for winter months.

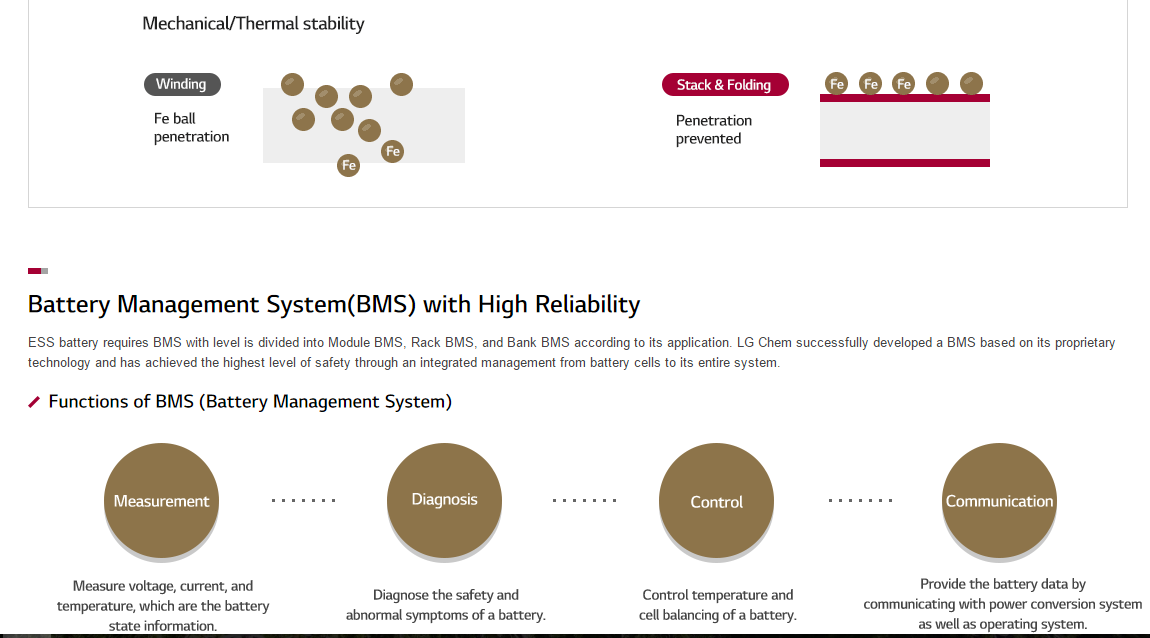

But worst of all, the example in that pic, while using 3.7v dumpster-dive componentry, (and not what we presume is new quality LiFeP04 in your case) is NOT the example you should follow. Note that some of the builders that do this, basically give the finger to *even their own community* when questions about safety and sanity are raised.

Basically, you won't get any support for stuff like that here.

That being said, cobbling together 160 cells, even if they are perfect, is not the way to go. For a housebank system, currently any LFP system is done with large prismatics (GBS, CALB, Winston etc) - NEW I might add - with the ideal of keeping your cell count low so you choose the highest capacity cells available according to your measured power needs.

If you just wing-it, especially with LFP, that will be an expensive lesson in not getting out the calculator, and throwing your wallet down the drain. Unless of course, your objective is to use garbage cells.

Can I even ask what exactly ARE your cells, and are they new? Are you sure they aren't counterfeit / rewraps / used cells. 26650's, or 32650's? At any rate, for a serious solar housebank, that is out of the question anyway.

This isn't going to be cheap, and trying to cheap-out with hundreds of cylindrical cells just shows that you are willing to cut corners in both safety and eventual performance. LFP aint cheap upfront so forget about trying to cut corners with hobbiest-style cockups.

Ok, so you blew $300. Perhaps you should get some gear to match them for both capacity and internal resistance, put them in small holders for say a low-capacity 12v battery, and get some practice handling them first.

Starting out trying to emulate Tesla with hobbiest-grade LFP cells just isn't the way to get off on the right foot. The catch 22 is that asking technical questions about how to go about it, means that you *desperately* need some real hands-on, and not just forum commentary.

-

For the sake of comparison you can buy a complete lithium battery pack (24 volts, 2.6 KWH) for $2600 from Torqeedo, a German electric outboard manufacturer. This includes a BMS system, safety features and a two year warranty. It is doubtful that you could build a similar DIY system for less. Thanks.

-

Interesting comparison, and I get your point, but by far the biggest mistake everyone makes, is not matching the lithium cells to the application at hand.

For instance, that Torqeedo bank is designed for high-current marine motive power, and not low-current multi-day autonomy as would be seen in a solar housebank. Thus, much of what you spend for super-high performance cells is wasted!

This mistake is seen from those coming from the RC and even EV field too. High-performance (super high-c capable) cells are a waste for an application like ours that is typically "sub-C", maybe .05C max where operations are typically 8 hours or longer. Talk about wasted dollars on a cell characteristic that one will never actually use - that is provided you have properly calculated the capacity of your bank to do so, and not just cobbling together some random handful of cells and seeing if it will power something.

That is why I always recommend anyone contemplating doing a diy of LFP, get some hands-on first with a very low capacity 12V / 4S simplistic system first. It will save you TONS of money - either by dropping the project altogether, or realizing that in many circumstances, lead-acid will do the required job just fine.

I love LFP, but I don't like wasting it's inherent capabilities on applications that don't demand it. Use it if you need it, but don't just do it cuz it's cool / l33t. Unless you like blowing money, or dumpster-diving with no real support.

-

You may want to re-read my post. Most of the questions you asked reside within that post. This is a smaller capacity system in which i'm more or less playing with to learn some lessons. It's going to drive a 100 watt hour load or so to start. So far my largest take-away from the information provided is ya'll like the word "cobble". I do mechanical design right now... i won't be cobbling. This is going to be a nice pack, with cell balancing, and the ability to remove/replace cells. All of my cells are 100% new and unused.PNjunction said:Hanslada - a few problems:

Forget the chemistry right now - this is the "ready, fire, aim" concept, which we don't follow here. That is, just cobbling stuff together, and throwing it at the wall to see what sticks.

Before you even begin, you have to know what your *actual* daily power needs are upfront. In addition, you need to know your solar-insolation hours, (which are vastly different than just sunrise-to-sunset hours), based on your geographical location and calculated for winter months.

But worst of all, the example in that pic, while using 3.7v dumpster-dive componentry, (and not what we presume is new quality LiFeP04 in your case) is NOT the example you should follow. Note that some of the builders that do this, basically give the finger to *even their own community* when questions about safety and sanity are raised.

Basically, you won't get any support for stuff like that here.

That being said, cobbling together 160 cells, even if they are perfect, is not the way to go. For a housebank system, currently any LFP system is done with large prismatics (GBS, CALB, Winston etc) - NEW I might add - with the ideal of keeping your cell count low so you choose the highest capacity cells available according to your measured power needs.

If you just wing-it, especially with LFP, that will be an expensive lesson in not getting out the calculator, and throwing your wallet down the drain. Unless of course, your objective is to use garbage cells.

Can I even ask what exactly ARE your cells, and are they new? Are you sure they aren't counterfeit / rewraps / used cells. 26650's, or 32650's? At any rate, for a serious solar housebank, that is out of the question anyway.

This isn't going to be cheap, and trying to cheap-out with hundreds of cylindrical cells just shows that you are willing to cut corners in both safety and eventual performance. LFP aint cheap upfront so forget about trying to cut corners with hobbiest-style cockups.

Ok, so you blew $300. Perhaps you should get some gear to match them for both capacity and internal resistance, put them in small holders for say a low-capacity 12v battery, and get some practice handling them first.

Starting out trying to emulate Tesla with hobbiest-grade LFP cells just isn't the way to get off on the right foot. The catch 22 is that asking technical questions about how to go about it, means that you *desperately* need some real hands-on, and not just forum commentary.

I understand your comfort in LFA or LA but consider this:

Home storage will go to lithium-ion regardless... Tesla is a huge drive for that. Their new 14kW powerwall is certainly lithium ion. And how does Tesla build lithium ion packs? With a very large quantity of cylindrical Ion cells. Do you know why? Because it doesn't make any sense to have a home power system when you need to purchase 4 grand in lead acid batteries every 5 years. Lithium iron's cycling ability far exceeds LA and that's comparing 1C discharge rates. At a 0.05C discharge do you have any idea how many cycles a life battery with last? Its also flat out safer than li-co or lipo. Lithium iron is already not much more expensive than LFA or LA and when you consider you'll be getting a lot more cycle life.

This is not the "ready, fire, aim" concept you have described here. I know exactly what i wish to attain as a goal and i know 98% of how i'm going to accomplish that. If this is not clear to you, start asking the correct questions.

I would like to point out to the uniformed here that Tesla also makes their car batteries out of approximately 7000 18650's. A smaller version of the exact same technology i'm going to be using. If you do not know what a 18650 is.... you do not even belong in this thread...

If using a high quantity of smaller cells were dangerous i'd be hard pressed to discover why it is currently the industry standard for EV's? You know an EV, that has to go through vigorous DOT safety testing before it can even hit the road... I'm not saying some of these concerns aren't valid... but they appear to be BROADLY unfounded.

And Tabby Cat i'd say you must be uninformed or really high. Tesla's powerwall is 14kw for $5000.

"(24 volts, 2.6 KWH) for $2600 from Torqeedo" -This is a rip-off 1000$ per kw? Are you kidding?

Again tesla sells powerwall @ 14kW for $5000. $357 per kW....................

Like junction mentioned, the application is not apples to apples. That battery is likely rated to 10C+ regular discharge. A home battery doesn't even need to run 0.5C. High discharge batteries cost more, simple as that.

-

Also for those interested take a look at the specification sheet of these cells before you assume too much. They show the safety tests done. Including over-charging a cell to 10V, over-discharge, puncture tests, and a short circuit test that will answer our first posters question. What happens when you short circuit a cell in a parallel chain? Nothing. Heat, maybe smoke, but no fire, and no explosion. This is why you will see these batteries used in the future for home installations.

http://www.all-battery.com/datasheet/30071_datasheet.pdf

-

I would take a good look at fine print in my homeowners insurance policy. A Tesla or LG (below) and other brands will meet UL1973 and UL 9540. There are good ways to build a battery for home use and some very bad ways.

Lead Acid is about $ 150 per KWH and when used correctly can easily last 10 years.

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Thanks for the reply Dave. I realize a custom made battery likely would not be covered under home-owners insurance. I also don't plan on keeping the batteries IN my house either. Most people who do these setups do battery sheds.Dave Angelini said:I would take a good look at fine print in my homeowners insurance policy. A Tesla or LG (below) and other brands will meet UL1973 and UL 9540. There are good ways to build a battery for home use and some very bad ways.

Lead Acid is about $ 150 per KWH and when used correctly can easily last 10 years.

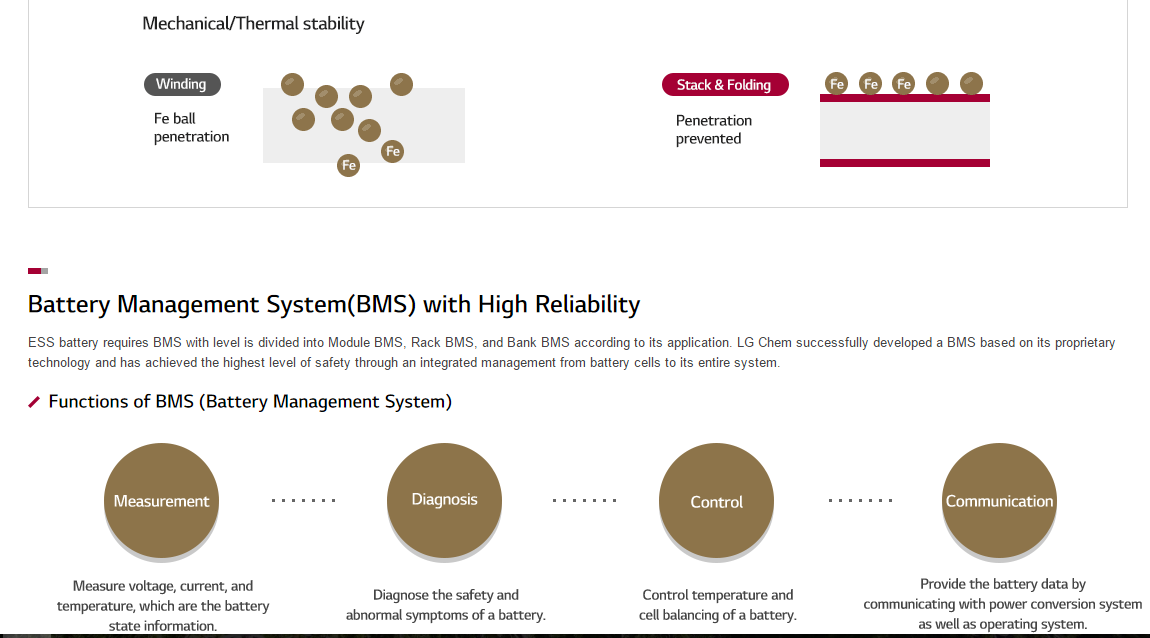

A Tesla or LG battery bank wont be too far off from what i'm making as far as the BMS goes. If you take a look at the road car's battery, they do not individually balance all 7000 cells of that battery. They run parallel chains and series those chains and balance those series. I can only imagine they do the same for their powerwall. In other words, they rely on good brand new cells to balance themselves within the parallel chain. And then they actively balance the 16 series cells.

I can't speak for the quality of these cells yet as i have not received them yet... but i can say, buying them in bulk from the manufacturer i'm only paying $120 per kW in raw cell form. I will have some money loss in building the pack and the controller. -

This is the cell fusing Tesla does off each parallel bar. I intend to do the very same thing. IF a cell goes totally short, or begins to massively drain others in the chain, it will short the fuse, and eliminate itself from the parallel line. The only result is a blown fusible link, which will be observable (noticable to replace), and a lower total amperage capacity on that line, which wont cause any harm to the series battery. Theoretically the cell will never reach dangerous temps (again life doesnt anyways) because current would be cut before it had a chance to go above say 10 amps off one cell.

-

I thought the Torqeedo would serve as a fair comparison since its' capacity is close to what you require. If it serves your purpose I'm willing to bet a DIY project is going to cost you a lot in time and money. An old sailor once told me that only a rich man can afford a bargain. Good luck.

-

handslada - I'm well aware of the advantages of LFP. Please read and find my own project here from years ago. Safe and sane with large-format prismatics like GBS, Winston, CALB. Look them up, although we covered nearly everything you are bringing up now.

What here is different from Tesla? The cells and construction techniques are pure unsafe crap. It will be the first thing that insurance companies will point to should there be an accident, or god forbid reach the stage of diy manslaughter. Grow up before you harm yourself or somebody else. Oh, you may get away with it for awhile, but that does not mean we have to support it.

It's not even a chemistry thing - the same objection would be raised if someone started a thread with "I just found four different flooded lead-acid batteries at the dump! How best should I charge them?"

Unfortunately, we've been down this road years ago when the flood of used / reject / counterfeit A123 LFP cells hit the market, and kids wanted to wire them all up with exposed bus-bars, wire-fuses, and their 1000w soldering iron. I just don't have the energy for this type of endless discussion any more.

My crystal ball says that very shortly, due to those trying to emulate Tesla unsafely, you won't be able to even purchase cells directly - only OEM's will be able to buy them, and diy'ers will have to rely on illegal sales. Trust me, your project will be very short term.

-

Yes, this is the way I would do it. I have 8 blocks of 4 90Ah batteries in parallel hooked together in series to make a nominal 24 volt battery, this is known as a 4P8S battery. This method averages out variations in the individual cell capacities and make the battery easier to balance and monitor. One comment, instantaneous power measured in Watts (W) = Voltage x Amps. Energy stored in a battery (Wh) = Voltage x Amps x (hours that the amps have been flowing). This is equivalent to Wh = BatteryVoltage x Ah.hanslanda said:

1)With 160 cells... do I want to parallel as many as I can, and series those parallel lines to achieve my desired voltage?

i.e. Wire 4 rows of 40 parallel cells to achieve 3.2v@ 220 amps, and then series those 4 chains to attain 12.8v @ 220amps?2) Choosing a voltage. Since i make my own panels.... voltage is not really any special requirement. I don't need a 12.8v system. It could be a 24v or 48v system. I would assume higher voltages are just better for power transmission... but the transmission distance to my AC inverter is only going to be a few feet anyways. Although using life batteries... I can see finding a charge controller that can balance charge 16 cells might be tricky. More or less i need help verifying my thought process on this.

As well as less transmission losses you also have to consider the fact that the maximum power output from solar charge controllers is limited by the current output. If you have a 20A controller it will be capable of charging at 240W for a 12V battery, 480W for a 24V battery and 960W for a 48V battery.3)Balance charging

LiFePO4 (LFP) batteries cannot balance themselves. Having said that my experience is that they go out of balance very slowly. Over a period of months. As they age they seem to go out of balance at a slower rate. It is very important to balance an LFP battery before you commission it.

Is it necessary with LifePO4? I see some say its absolutely critical... and others who say Life can balance itself much like Lead acid due to its larger than Lipo overcharge tolerance.4)Balance charging with MPPT. Do MPPT chargers have this ability? Would it be desirable? Otherwise on the charging front i see hobby chargers work very well. Its just a hobby charger wouldn't work with a solar application. I need some form of MPPT that knows how many cells i have much like a hobby charger, and with the abilitiy to balance those cells.

Not to my knowledge, the MPPT controller will only regulate the overall battery voltage. Having said that if your battery is in balance overall battery voltage is all that needs to be regulated. For solar charging I think a very good charging regime is to charge the cells with the bulk voltage set to 3.45V/cell (13.8V for a 12 volt battery) and floating at 3.35V/cell (13.4V for 12V)5)BMS iv'e heard good and bad things about BMS's. Some have fried and destroyed packs. Others have prolonged battery life to 5 years. My question here is; would the answer to my solution be to run a standard 'off the shelf' MPPT to a BMS that manages the cells? I feel that's where i'm headed.

A BMS does a number of functions, some/all of these functions can be done by a human with a multimeter or some/all can be automated. The choice is up to your technical ability, how much you want to automate the process and how user proof you want the battery to be.

As a bare minimum I would suggest a cell monitor like a Cellog 8 to monitor the individual cell voltages. The Cellog 8 will also generate an alarm and can also be used to stop charging or disconnect loads if any cell goes out of its safe operating voltage range.

The other important function of a BMS is to keep the battery balanced. This can be done manually by keeping an eye on the individual cell voltages. When they diverge too far when the battery is at the end of charging a simple resistor load can be placed across the cells which are too high to remove some charge from them. If you have automatic balancing I would recommend having cell voltage monitoring as well to tell you if the balancing circuit has failed.

If you want an intelligent programmable BMS. I haven't tried this one, but on paper I think http://123smartbms.com/ is the best commercial unit available at the moment.6)BMS/MPPT charger ratings.

The better fully automatic BMS units available will disconnect the battery from the charger and loads in the event that any cells go outside the safe operating region. The components that disconnect the battery have to be rated at a current carrying capacity greater that the current that the solar controller will supply or the load will consume. Limiting the discharge current to 0.5C (half the battery capacity in Ah) and the charge current to 0.2C and keeping the battery balanced should give you longer battery life.

When i see a battery management system with an amperage rating, is that rating intended to be above the value of the battery? Or is it more or less the max discharge/charge rate? Same question on MPPT's. I assume the latter and more specifically it would pertain to the max charge rate of the battery or the max drain rate, which my load will depend on as well.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

I like the idea of individually fusing each cell. You will have to be careful that all the fusible links are the same length and that the bus bars that they are soldered to have a large enough cross sectional area to carry and balance the current going too/from the individual cells.hanslanda said:This is the cell fusing Tesla does off each parallel bar. I intend to do the very same thing. IF a cell goes totally short, or begins to massively drain others in the chain, it will short the fuse, and eliminate itself from the parallel line. The only result is a blown fusible link, which will be observable (noticable to replace), and a lower total amperage capacity on that line, which wont cause any harm to the series battery. Theoretically the cell will never reach dangerous temps (again life doesnt anyways) because current would be cut before it had a chance to go above say 10 amps off one cell.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

i like the 4p configuration of cells like this. as everyone is worried about heat, it about the only real way you can feel the cells individually with your fingers600 watts of solar panels,Epever 30 mppt , 2 PWHR12500W4FR battery's in 24 volt setup

-

In my opinion, heat sensing is the last ditch fault detection, If it's starting to cook, pull the cables and haul it out doors, it's going up. It means an internal fault in a cell, that's the only way they heat up, because Internal Resistance is so low.DConlyGuy said:i like the 4p configuration of cells like this. as everyone is worried about heat, it about the only real way you can feel the cells individually with your fingers

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

well that why i like the 4p if it anymore you cant feel the heat id rather be just that one step safer than not600 watts of solar panels,Epever 30 mppt , 2 PWHR12500W4FR battery's in 24 volt setup

-

Whew, glad I don't have to go over this again by myself.

My new year's resolution is not to get suckered into toy projects ever again.

We STILL do not know if the op has verified that his cells are legit. Even something as simple as matching for both capacity and internal resistance has not been done. Everything beyond this is a meaningless technical exercise wasting server space.

You all know that these projects are predicated upon starting out with TRASH to keep costs down from using legit products. His homebrew solar panel, unless it is used solely for education, and not real production is another red-flag for the real purpose of dumpster diving.

You guys have fun. At this point for me it is a big YAWN.

-

Karrak, very informative post and a HUGE help. I also am considering how to maintain the thermal management system. I am thinking of a thermal transfer fluid that would allow me to monitor temperature in just 6-8 places in each parallel bank. This will also show temp deviations much faster if one were to arise. I've used mineral oil in powered applications before, although I'd prefer to use a non-hydrocarbon that is completely inherit such as silicone oil. The only real downside to silicone oil is it's cost.

PNjunction I wish we could come to common ground on this but it just doesn't seem possible. You have some preconceived notion as to a motive of mine to save money. That's not my intent. For the record, and I mentioned this already, I haven't received the cells yet. I did not dumpster dive for them lol. They are coming from tenergy as is the tenergy charger. I very much plan to test each cell before I build anything.

As for my home-made solar panels... there's a reason I build my own. The cell I prefer is not commercially available on a consumer level. Check out the spec sheet for the maxeon C60 and tell me you don't want it all over your roof...

Feel free to ask me anything you like, maybe if you did that you wouldn't be so quick to criticize. But all you've done here is bash and criticize and assume. If that's going to be the sum of the quality of your posts, then please just don't post. I don't want to argue and criticize but trust me I know how to. -

Just remember that a certain "battery expert" keeps saying that the Chinese LFP batteries that you and I have are rubbish and will never last the distance ...PNjunction said:You all know that these projects are predicated upon starting out with TRASH to keep costs down from using legit products. His homebrew solar panel, unless it is used solely for education, and not real production is another red-flag for the real purpose of dumpster diving.

As for home brew, if the person knows what they are doing they might make a product that is better than anything that can be bought because they don't have any marketing constraints like cost, planned obsolescence etc.

What about the fun and sense of achievement designing and building ones own equipment.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

I am wondering if you need a thermal management system unless your battery is going to be installed in very adverse climatic conditions (>40C[~105F] or <0C[~32F]). My understanding is that because of the lower cell voltage that LFP batteries run at compared to LCO (Lithium Cobalt as found in Laptops etc) and LMC (Lithium Manganese Cobalt as found in cars and the Powerwall 2) that they should inherently have a longer lifespan so unless you are going for a lifespan of maybe 20 years + or have a large expensive battery I am not sure it is worth having any thermal management.hanslanda said:I also am considering how to maintain the thermal management system. I am thinking of a thermal transfer fluid that would allow me to monitor temperature in just 6-8 places in each parallel bank. This will also show temp deviations much faster if one were to arise. I've used mineral oil in powered applications before, although I'd prefer to use a non-hydrocarbon that is completely inherit such as silicone oil. The only real downside to silicone oil is it's cost.

With standard offgrid usage the battery is not going to get hot due to self heating.

Simon

Off-Grid with LFP (LiFePO4) battery, battery Installed April 2013

32x90Ah Winston cells 2p16s (48V), MPP Solar PIP5048MS 5kW Inverter/80A MPPT controller/60A charger, 1900W of Solar Panels

modified BMS based on TI bq769x0 cell monitors.

Homemade overall system monitoring and power management https://github.com/simat/BatteryMonitor

-

Throw some perspective on this too. If you had a cell short out in your home, would you rather it be a huge 200 amp 6v cell sealed batt, or a single 3.2v 5amp cell?

Thermal mgmt I was thinking more or less as a double safety to the individual cell fuses. In the event a cell does short, I might not see a temp diff unless I'm right there to see it happen. A cell could float at 60c before a air temp sensor would pick that up nearby. So if I partially submerge the cells in mineral or silicone oil, when a cell heats up (due to failure, and assuming fuse failure) it will heat the oil up much faster, and I should be able to pick that up on a temp sensor faster. I already have a micro controller setup to monitor temps with a disconnect.

I've also seen people attempt to blow battery's submerged in mineral oil and the mineral oil seems to somewhat insulate the battery failure. Let me see if I can find some information on that. -

1. Unless the temperature sensor is in direct contact with a cell it is unlikely that it will sense anything in time to do anything about a massive internal failure in the cell. It is there more to detect the onset of thermal runaway during charging when you cannot measure cell current and voltage at each cell.hanslanda said:Throw some perspective on this too. If you had a cell short out in your home, would you rather it be a huge 200 amp 6v cell sealed batt, or a single 3.2v 5amp cell?

Thermal mgmt I was thinking more or less as a double safety to the individual cell fuses. In the event a cell does short, I might not see a temp diff unless I'm right there to see it happen. A cell could float at 60c before a air temp sensor would pick that up nearby. So if I partially submerge the cells in mineral or silicone oil, when a cell heats up (due to failure, and assuming fuse failure) it will heat the oil up much faster, and I should be able to pick that up on a temp sensor faster. I already have a micro controller setup to monitor temps with a disconnect.

I've also seen people attempt to blow battery's submerged in mineral oil and the mineral oil seems to somewhat insulate the battery failure. Let me see if I can find some information on that.

2. The presence of the oil, especially if forced to circulate, may act like the fire department water curtain when trying to save a building adjacent to the fire. It keeps the temperature of the adjacent batteries from reaching critical levels. This did not happen in the case of the Boeing battery, for example, leading to the whole pack melting down and burning.

SMA SB 3000, old BP panels. -

Very interesting. I read about boeing failures and how tesla avoided that. It seems like the boeing's battery didn't circulate, for whatever reason tho i'm having trouble validating that. I know tesla does circulate as needed.inetdog said:

1. Unless the temperature sensor is in direct contact with a cell it is unlikely that it will sense anything in time to do anything about a massive internal failure in the cell. It is there more to detect the onset of thermal runaway during charging when you cannot measure cell current and voltage at each cell.hanslanda said:Throw some perspective on this too. If you had a cell short out in your home, would you rather it be a huge 200 amp 6v cell sealed batt, or a single 3.2v 5amp cell?

Thermal mgmt I was thinking more or less as a double safety to the individual cell fuses. In the event a cell does short, I might not see a temp diff unless I'm right there to see it happen. A cell could float at 60c before a air temp sensor would pick that up nearby. So if I partially submerge the cells in mineral or silicone oil, when a cell heats up (due to failure, and assuming fuse failure) it will heat the oil up much faster, and I should be able to pick that up on a temp sensor faster. I already have a micro controller setup to monitor temps with a disconnect.

I've also seen people attempt to blow battery's submerged in mineral oil and the mineral oil seems to somewhat insulate the battery failure. Let me see if I can find some information on that.

2. The presence of the oil, especially if forced to circulate, may act like the fire department water curtain when trying to save a building adjacent to the fire. It keeps the temperature of the adjacent batteries from reaching critical levels. This did not happen in the case of the Boeing battery, for example, leading to the whole pack melting down and burning.

My thought was to have the oil circulate on detection. Like mentioned, my low charge rates and discharge rates shouldn't generate enough heat to need to have it actively cooled. My thought was once a temp sensor detects an increase in ambient oil temp (say a specific raise in temp over a specific time sample, to activate circulation as an emergency measure. Like you mentioned this is merely to mitigate further cell damage of the unaffected cells, and also to potentially insulate the cell failure. I can have that same oil loop run through a 480mm radiator with some fans to actively cool the oil. I have an arduino coded to do this basically already from another diy project. It also has cellular, so i can have my battery call or text me when it overheats :-P

-

Very interesting. I read about boeing failures and how tesla avoided that. It seems like the boeing's battery didn't circulate, for whatever reason tho i'm having trouble validating that. I know tesla does circulate as needed.

Nothing that I saw in descriptions or photographs about the Boeing debacle suggested to me that there was any oil bath at all, let alone circulating coolant. They had a temperature sensor on one of the terminals of each cell in the battery. But once one cell went into runaway, nothing that could be done externally could stop the heat from driving the adjacent cells into failure too.

SMA SB 3000, old BP panels.

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed

https://www.youtube.com/watch?v=_A8R9aUbwkw

https://www.youtube.com/watch?v=_A8R9aUbwkw