Schneider MPPT 60 150 compartment divider - ok to remove/drill through?

jjdh

Registered Users Posts: 9 ✭✭

I have a new MPPT 60 150 charge controller, and I have an already-installed Conext "DC Switchgear". As per the Schneider website and documentation for the Switchgear, these are supposed to be designed to go together.

The way they mount means the charge controller goes on the left of the Switchgear, with matching knockouts on each device and some mounting screws to hold them to each other, all good. The final setup would look something like this:

The way they mount means the charge controller goes on the left of the Switchgear, with matching knockouts on each device and some mounting screws to hold them to each other, all good. The final setup would look something like this:

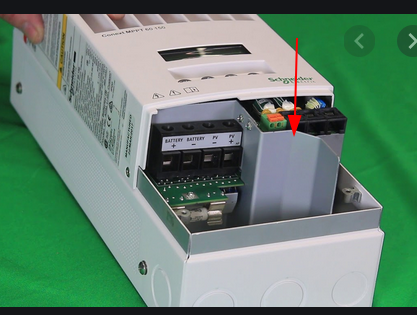

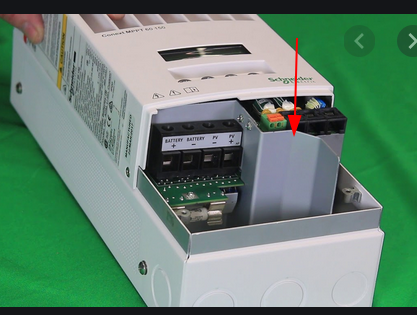

Here's my problem. The charge controller has a metal separator inside, to keep the PV / Battery DC wiring separated from the signal wiring. Fine. Except.. that divider means there's no path to route wires from the switchgear, through the shared KO:

So: Am I gonna need to run separate conduit for the DC wires, or is it ok to remove/drill a hole through the separator?

It seems backwards to me - I thought these products were specifically designed to be mounted like this. In the end, all the wires - both Battery DC and signal wires - go into the switchgear anyway.. I guess there would be a greater risk of interference if they all go through the same small KO than if they enter the switchgear separately?

So: Am I gonna need to run separate conduit for the DC wires, or is it ok to remove/drill a hole through the separator?

It seems backwards to me - I thought these products were specifically designed to be mounted like this. In the end, all the wires - both Battery DC and signal wires - go into the switchgear anyway.. I guess there would be a greater risk of interference if they all go through the same small KO than if they enter the switchgear separately?

Tagged:

Comments

-

Oh man. I wrote this, got up and walked over to the charger and realized what I'm missing. The charge controller doesn't mount flush to the wall, it mounts with enough space to route conduit behind it and into the switchgear.

Sorry for the noise!

-

I am happy to hear you found the solution... The separation between DC power and "low voltage" control/communications wiring--The NEC requirement is (more or less) that "different" electrical circuits need to be in separate conduit/routing channels. I.e., If you have DC control wiring and high(er) voltage/power, they cannot be run together (even if the insulation requirements are met that all insulation meets the highest voltage in the shared space).

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Another reason to follow the manual is EMC. FCC and Industry Canada (Class

, CE marked for the EMC Directive (EN61000-6-1, -6-3), C-Tick compliant. This was one of the first mppt charge controllers back in 2006 to meet these specifications.

, CE marked for the EMC Directive (EN61000-6-1, -6-3), C-Tick compliant. This was one of the first mppt charge controllers back in 2006 to meet these specifications.

Run the network cables in their raceways as per the manual and avoid the temptation to be lazy. Drilled holes are another way to have warranty denied. Good luck"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net

Categories

- All Categories

- 233 Forum & Website

- 141 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed