Building a Battery Cap Temperature Sensor

I began by studying blackcherry's design with the accompanying comments and looked around my place. I already had an Outback BTS (you know, one of those left-over pieces after you get your toy "completely" assembled) and I began by removing the sensing element from its case. I accomplished this by using a small triangle file to mill down the edges and lifted-off the surrounding plastic. A Dremel would probably work better, but not having one that was operative, the file just required more time and patience.

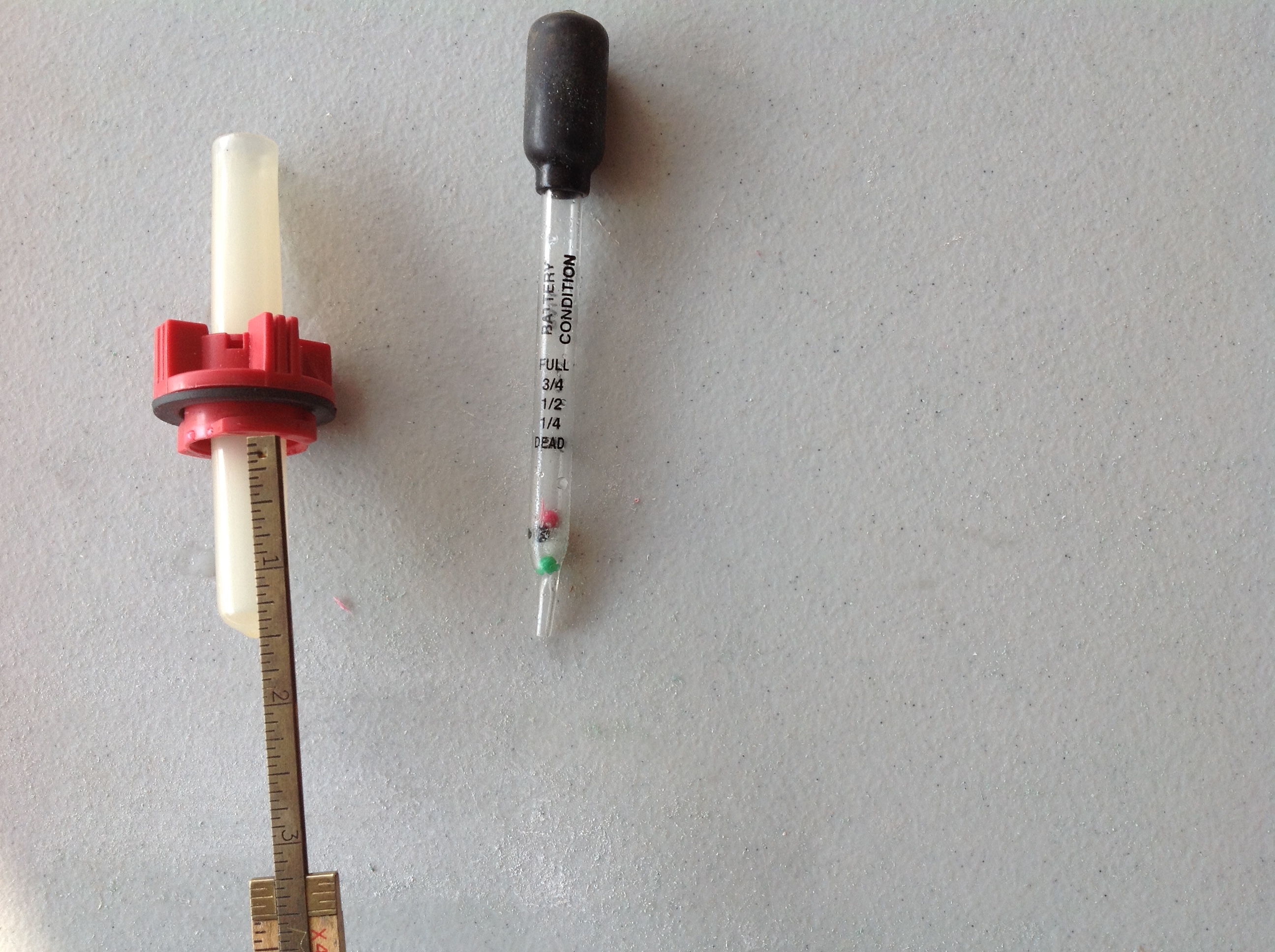

After studying the configuration of the raw Outback sensing element and the battery cap I proposed to used, I discovered the perfect device to use for the insert. I know just about everyone viewing this forum either has one of these devices, right now, or you had one at some time, or you know exactly where to buy one. It's the reliable el-cheapo squeeze-bulb battery hydrometer with the 3 little floating balls. You use the outer case of the hydrometer for the insert.

I continued to file down the epoxy housing on the sensing unit so it would fit into the squeeze-bulb case and I used a 1/2" drill in the battery cap for the insert. It's a tight fit.

I measured the depth for the insert, stuck it in the battery cap and re-measured before I cut off the excess.

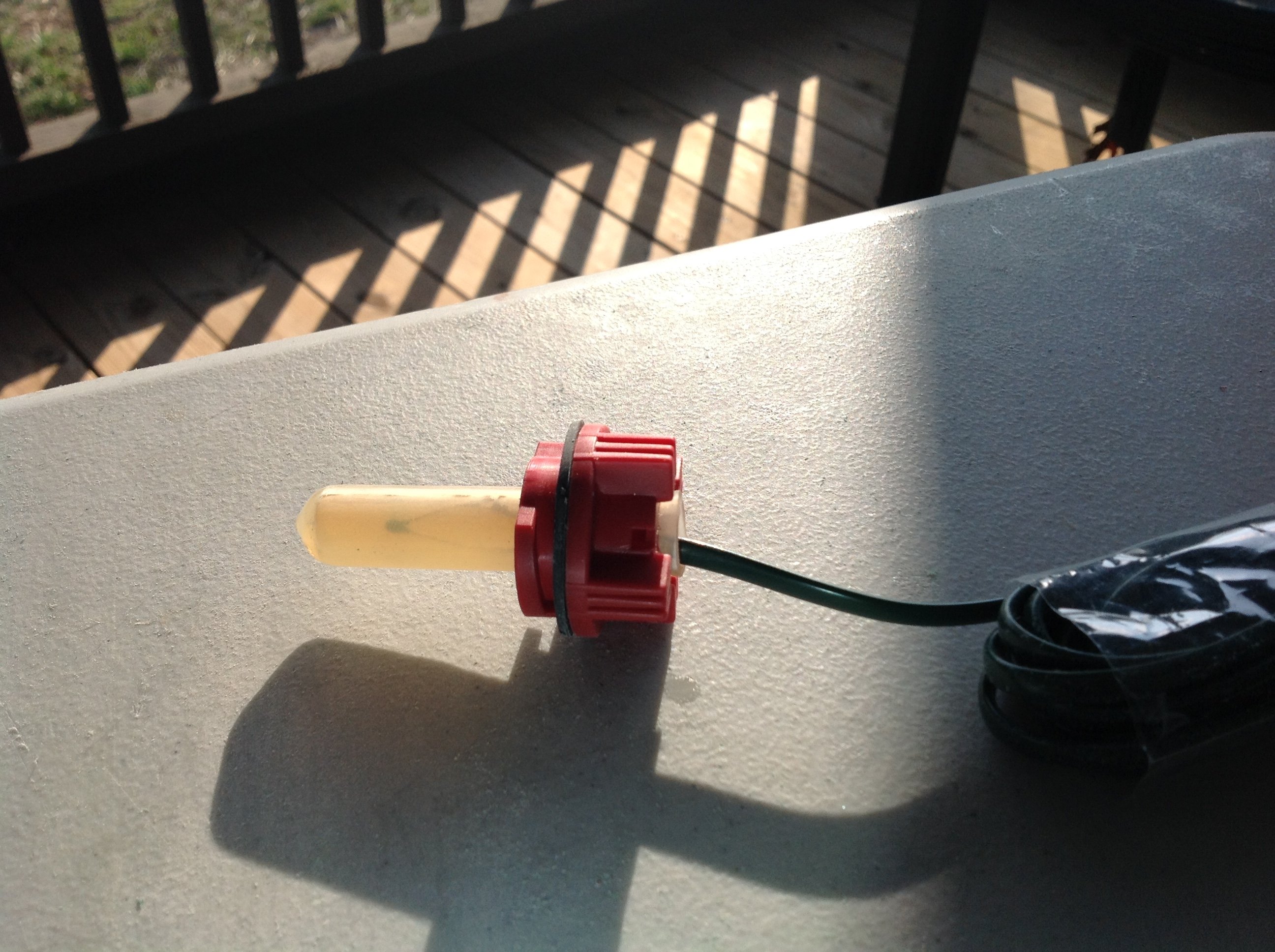

Here's the "almost finished" product. I need to fill-in the top with glue or silicone cualk. Going to look around and see what I have available.

I made this post becuase making this device is not extremely complicated (I was able to do it) and primarily because, the insert device can be so easily obtained and the tools needed are common. And, most importantly, I hope others will benefit from this endeavor.

My sincere thanks to blackcherry.

Paul

in Georgia

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k

Comments

-

Anawa, congratulations on your success. It'll now be able now give you the exact temperature of the electrolyte, that is to me is what counts and it reacts real time without any lag. Measuring it through the case and factoring in the ambient effect was something I couldn't deal with. Good Luck.

-

If that is plastic (not glass), you should look at a chemical reistance chart and ensure that it is compatible with your choosen materials:

http://www.plasticsintl.com/plastics_chemical_resistence_chart.html

-Bill

Near San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Humm, BB, hope you can help me on this. I may have acted a bit impulsively, but I guess I was thinking that since I've had this hydrometer for about 10 years, it's had electrolyte residue inside the case during this time, and the manufacturer thought it was appropriate, is this something I need to worry about? I'm not trying to be arrogant, I really don't know and besides, the resistance chart is completely foreign to me.

Paul

in GeorgiaPaul

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k -

Hi Anawa,

Thanks to Bc04 for adding this to the list of possible solutions.

I, too had wondered about the compatibility of that plastic with electrolyte -- I have always worried more about the effect of materials like this on the purity of the electrolyte, and that possible effect, rather than the effect of the electrolyte on the plastic.

As an aside, believe that the Thermistor, which is what the Sensor is called, is a 10K ohm NTC unit, for OB Power products. This can be confirmed with a simple DMM measurement. NTC, means Negative Temperature Coefficient, which means that the resistance decreases with increase in temperature. Believe that the thermistor on most Solar products is connected between the two center pins of the telephone-style plug.

FWIW, here is an inexpensive Bead Thermistor, with attached leads which could seed things along:

Believe that the MidNite BTS is also 10 K, and will need confirm that upon returning to one of the remote sites.

Vic

Off Grid - Two systems -- 4 SW+ 5548 Inverters, Surrette 4KS25 1280 AH X2@48V, 11.1 KW STC PV, 4X MidNite Classic 150 w/ WBjrs, Beta KID on S-530s, MX-60s, MN Bkrs/Boxes. 25 KVA Polyphase Kubota diesel, Honda Eu6500isa, Eu3000is-es, Eu2000, Eu1000 gensets. Thanks Wind-Sun for this great Forum. -

Vic, Got it on the electrolyte purity. The Mouser thermistor looks very similar to the OB unit.

I'm not sure what to do about the plastic insert in determining compatibility. I do not have a clue what kind of plastic it is. Heck, I can not remember where I bought it!

Thanks

PaulPaul

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k -

The sensors that bolt on the battery terminals that the XW and old SW use have been fine for decades BTW. Why can't they be used on this battery and save a ton of time? Just curious?Blackcherry04 said:Anawa, congratulations on your success. It'll now be able now give you the exact temperature of the electrolyte, that is to me is what counts and it reacts real time without any lag. Measuring it through the case and factoring in the ambient effect was something I couldn't deal with. Good Luck."we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Hi Anawa,

Bc04 mentioned using a small glass vial. These are quite commonly used in the Perfume and "Essential Oil" trade.

Just Searched for ' glass vial ' , and there are many hits, quite a few on Amazon. Most of the listings do not give dimensions, but, rather, the vial's volume. It might be possible to contact some of the sellers and ask for the dimensions. Also, some seem to be quite thin, and might be too delicate for your use.

Glass would seem to be a superior material, although it might a bit more difficult to come up with a press-fit seal.

FWIW, Good Luck, and am sure that you will let us know what you find. Thanks again, Vic

Off Grid - Two systems -- 4 SW+ 5548 Inverters, Surrette 4KS25 1280 AH X2@48V, 11.1 KW STC PV, 4X MidNite Classic 150 w/ WBjrs, Beta KID on S-530s, MX-60s, MN Bkrs/Boxes. 25 KVA Polyphase Kubota diesel, Honda Eu6500isa, Eu3000is-es, Eu2000, Eu1000 gensets. Thanks Wind-Sun for this great Forum. -

I had carburetors on cars for 40 years and they worked fine until I got the first one with Fuel Injection, now I'd never go back. It's just another way to skin a cat. If what you have works for you, stick with it. I think you'll find that as the automotive industry moves to different technologies they will have temperature sensors built in, LiFepo4 comes to mind.Dave Angelini said:

The sensors that bolt on the battery terminals that the XW and old SW use have been fine for decades BTW. Why can't they be used on this battery and save a ton of time? Just curious?Blackcherry04 said:Anawa, congratulations on your success. It'll now be able now give you the exact temperature of the electrolyte, that is to me is what counts and it reacts real time without any lag. Measuring it through the case and factoring in the ambient effect was something I couldn't deal with. Good Luck.

-

I really can't go along with your analogy. The temp at the lead terminal or the middle to 2/3 up the case is going to be almost exactly the same for a lead acid battery as in the electrolyte on the large lead acid batteries we use. The XW being developed used the lead terminal for their sensor and still does 10 years later. Alot of engineering went in and good field data to back the design.

The LiFepo4 is a completely different technology and from the teething stories I have been hearing they should probably have 3 sensors per cell to protect the battery. That is how Lockheed Martin did it a ways back."we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Great info, everyone. I'm going to order the sensor Vic referenced and attach it to a phone type connector. I'm going to try to find a glass vial or enclosure rather than plastic just because I think my mind would rest more easily! Looks like a good plan. Thanks again.

1st system: 24Vsystem with 8 X 300W panels, Midnite Solar combiner box, Midnite Solar mini-dc disconnect, Midnite Solar Classic 150, Outback VFX 3524 with mate, 2 X 12V fforklift batteries in series 938 aH, (Outback PSX transformer, Honda EU3000is...not currently hooked up but available if/when needed)

2nd system: 24V system with 4 X 310W panels, Midnite Solar combiner box, Midnite Solar mini-dc disconnect, Midnite Solar Classic 200, Cotek 1500W pure sine inverter, Trojan 125 batteries (8 available but "currently" using 4) -

Hi elesaver,

1. I should really confirm that the MN BTS IS 10K ohn at 25 C.

2. Should also check the current that a Classic runs through the Thermistor. The Linked Thermistor has a rating of only 60 milliwatts, IIRC. There could be a bit too much self-heating on a Thermistor that small.

Will try to confirm the above this evening ... I have never seen the thermistor used inside either the OB, or the MN RTS/BTSes.

More Later, Vic

Off Grid - Two systems -- 4 SW+ 5548 Inverters, Surrette 4KS25 1280 AH X2@48V, 11.1 KW STC PV, 4X MidNite Classic 150 w/ WBjrs, Beta KID on S-530s, MX-60s, MN Bkrs/Boxes. 25 KVA Polyphase Kubota diesel, Honda Eu6500isa, Eu3000is-es, Eu2000, Eu1000 gensets. Thanks Wind-Sun for this great Forum. -

It's a 10K at 77° F ( 25° C ) on Outback products. boB and Robin Gudgel must have taken the same scheme to MidNite. The wiring on the OB is red & black paired and the green & yellow paired. That doesn't mean that all conductors in the receptacle are connected and active.

A Xantrex I did used a 10k thermistor and had a 10k ballast resister in series attached to it. I don't know the scheme or why theirs is different, maybe something brought over from Trace and not on their boards. The wiring is Red, ( black not connected ) and green & yellow paired.

-

YES, had read somewhere that the MidNite and the OB were the same -- 10 K NTC @ 25C

Checked an OB with a bat temp of 7.9C and that was 20.6 K ohm

The MN Classic's BTS was reading 22.1 K ohm.The above might look to be a fairly large discrepancy, but there is quite a range in resistance change for relatively small changes in temps. Each of the above sensors were on a single large battery, under 2" Styrofoam, FWIW.

Did not have sensors that could be placed on a 25 C plate, but am sure that the Thermistor is 10 K at 25 C, and definitely NTC.

YES, EDIT: the Red and Green are two conductors used on both the OB and MN RTS/BTSes. I did not test the remaining two wires -- the Bk and Yel, and they may well be paired on either of both the OB and MN BTSes. Also, note that I have NO FM CCs, or OB inverters, so, the OB sensor was from an early MX-60. And, I have not ever dissected any manufacturer's RTS/BTS. Have read, elsewhere from a MidNite tech person, that only two wires are used for the BTS, and that those were the two center pins of the phone plug < End EDIT>

At the 25 C reference temp, the OB MX-60 shows a nominal self-heating of about 2.5 milliwatts, and the Classic, a bit less, as it's reference is a lower voltage. This should not be any issue at all.

Good Luck, Vic

Off Grid - Two systems -- 4 SW+ 5548 Inverters, Surrette 4KS25 1280 AH X2@48V, 11.1 KW STC PV, 4X MidNite Classic 150 w/ WBjrs, Beta KID on S-530s, MX-60s, MN Bkrs/Boxes. 25 KVA Polyphase Kubota diesel, Honda Eu6500isa, Eu3000is-es, Eu2000, Eu1000 gensets. Thanks Wind-Sun for this great Forum. -

I am sure it is the Red & Black paired and the Yellow and Green paired. In this blow up it's hard to see the black, but the yellow and Green are easy to see on one side.

-

I'll confirm the wiring in the AM..

Paul

in GeorgiaPaul

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k -

Blackcherry04 said:I am sure it is the Red & Black paired and the Yellow and Green paired. In this blow up it's hard to see the black, but the yellow and Green are easy to see on one side.

YES, you are probably correct about pairing of the four wires in the phone cable, I only used the Red and Green (I did say red and black ... but this was wrong).

To me, this is what will give dial-tone on an old POTS cable. It was difficult to probe as all of the BTSes were in use, and had to use all three hands to try to hold the multimeter, probes, and a phone wall jack with the flashlight in my mouth at the same time.

Sorry for the misinformation, been quite busy, and just tried to bang this out. FWIW, Vic

Off Grid - Two systems -- 4 SW+ 5548 Inverters, Surrette 4KS25 1280 AH X2@48V, 11.1 KW STC PV, 4X MidNite Classic 150 w/ WBjrs, Beta KID on S-530s, MX-60s, MN Bkrs/Boxes. 25 KVA Polyphase Kubota diesel, Honda Eu6500isa, Eu3000is-es, Eu2000, Eu1000 gensets. Thanks Wind-Sun for this great Forum. -

Here's a better close-up of the wiring connection.

Paul

in GeorgiaPaul

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k -

I have one more cap modification that works great on industrial batteries. You can install a " Blinky " and install the grommet in a cap without drilling the battery case. It takes a lot of effort out of checking the water level each cell. If you find one cell that uses more than the others you can move the cap to that cell. You can usually find them on e-bay for $15 or so. They work on 2v cell voltage. and the probe's come in different lengths, buy the longest , easy to cut off. These will work on any 2V cell bank, I have one installed on a bank of Surrett's.

Sorry I don't have a picture of it installed in a cap. I know, looking in each cell has worked for a century, but there are things you can do that make things better. Now, if we could just get a remote SG monitor, things would be a lot easier.

http://www.phlsci.com/product/2/14

-

Interesting... it claims to be "UL Classified". What does that mean?Blackcherry04 said:You can install a " Blinky " and install the grommet in a cap without drilling the battery case.

<snip>

http://www.phlsci.com/product/2/14

--vtMaps

4 X 235watt Samsung, Midnite ePanel, Outback VFX3524 FM60 & mate, 4 Interstate L16, trimetric, Honda eu2000i -

Internally fused ?? I know it has something, because I tried hooking one up wrong and it wouldn't work after that and it was potted in epoxy.vtmaps said:

Interesting... it claims to be "UL Classified". What does that mean?

--vtMaps

-

Their website claims it is fused. If you can't see the fuse, then it must be potted. --vtMapsBlackcherry04 said:Internally fused ?? I know it has something, because I tried hooking one up wrong and it wouldn't work after that and it was potted in epoxy.

4 X 235watt Samsung, Midnite ePanel, Outback VFX3524 FM60 & mate, 4 Interstate L16, trimetric, Honda eu2000i -

The resistance tailors the curve to be calibrated. Just as there are at least 5 or 6 different curves for the thermistors. The component is often marked with paint on the ends. The body color and the paint color allows one to separate the different components. This allows one to customize the correction in an electronic circuit.Blackcherry04 said:It's a 10K at 77° F ( 25° C ) on Outback products. boB and Robin Gudgel must have taken the same scheme to MidNite. The wiring on the OB is red & black paired and the green & yellow paired. That doesn't mean that all conductors in the receptacle are connected and active.

A Xantrex I did used a 10k thermistor and had a 10k ballast resister in series attached to it. I don't know the scheme or why theirs is different, maybe something brought over from Trace and not on their boards. The wiring is Red, ( black not connected ) and green & yellow paired.

I use to use these from Omega at one time.

http://www.omega.com/temperature/Z/pdf/z256-257.pdf

If I even thought this was worth the effort I would make sure and verify the temp correction over the range and verify, not easy!

The other way would be to use the same part that the company uses!

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Yes, there are a number of Thermistor curves.

Checking a candidate Thermistor is relatively simple, if one is willing to do the simple three point temperature comparison of resistance values between the candidate Thermistor, and the reference BTS/RTS.

A slurry of ice would be the low temperature, and boiling water would be the other easy one. 25 C is a bit more difficult ... but if the curves match well, a small variation in the exact temperature in the 25 C range should not be too much of a concern.

Just try to minimize the self-heating, allow a reasonably long soak time at each temperature, and one should be able to confirm the curve match between the candidate and the reference (the BTS/RTS).

IMO, but this is not something that I will be doing ... Good Luck, Vic

Off Grid - Two systems -- 4 SW+ 5548 Inverters, Surrette 4KS25 1280 AH X2@48V, 11.1 KW STC PV, 4X MidNite Classic 150 w/ WBjrs, Beta KID on S-530s, MX-60s, MN Bkrs/Boxes. 25 KVA Polyphase Kubota diesel, Honda Eu6500isa, Eu3000is-es, Eu2000, Eu1000 gensets. Thanks Wind-Sun for this great Forum. -

Guys I would be willing to alter few caps if needed. I have a small machine shop and that project would be a piece of cake.

-

Hey Dave, not sure who you're calling "guys", but since I'm the OP, let's talk. Apparently, the plastic insert is a bummer, I don't have much of a shop, nor do I have very sophisticated electronic skills. Glass is good, at least that's the impression I'm getting. Got any suggestions? I'm listening.

Paul

in GeorgiaPaul

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k -

OK so dimensions come first, how high is the cap and how far does the tube need to extend off the bottom cap. What diameter tube is needed? Seems to me the existing supplied thermistor or a replacement could simple be potted in with a bit of silicon or epoxy.Anawa said:Hey Dave, not sure who you're calling "guys", but since I'm the OP, let's talk. Apparently, the plastic insert is a bummer, I don't have much of a shop, nor do I have very sophisticated electronic skills. Glass is good, at least that's the impression I'm getting. Got any suggestions? I'm listening.

Paul

in Georgia -

Dave, I would think that using a new thermistor would simplify this project. Getting the existing one out of its epoxy is not something I feel comfortable with. I think the eBay glass vials is a way to proceed, but would require a new thermistor. What's your thoughts on the other posts about buying the "right" one with issues about "curves" and such?

PaulPaul

in Georgia

System 1: PV- 410w Evergreen, Mppt- Blue Sky Solar Boost, Batt - 225ah Deka AGM, 12v led house lighting,

System 2: PV- 215w Kyocera, PWM - Morningstar PS30, Batt- 225ah Deka GC's, 12v led house lighting, Dankoff 12v water pump,

System 3: PV- 1.5kw Kyocera, Grundfos 11 SQF well pump, 3000 gal above ground water storage, dom water & irrigation,

System 4: PV- 6.1kw Kyocera, Mppt- Outback FM80-2ea, Inverter- Outback FX3648-2ea, Batt- 804ah GB traction, Grundfos BMQE booster pump 240v, Mitsibushi mini-splits 240v, 18k and 15k -

Well I certainly would hope that someone who has used like a Mouser part number could comment. I really know my grid tie system and not these battery charger controllers. I suspect if we could get one with the proper resistance and range that the curve could be off a little.

I agree on the Ebay vials that makes it pretty easy, but again the rub is dimensions. Before you can look you need to know the size required. -

Too bad you are so far away. I would give you an old outback sensor. My take here is use the 48 volt compensation curve from Outback, verify accurately the temperature around your batteries and use whatever you want. Verify that your new device is doing what it is suppose to over a wide range of temps that they will be exposed to.

I still can't see why you can't get an outback sensor to work. Too busy to read this again. good Luck!"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Paul, I just reread this thread and noticed in your close-up picture that you have Water-Miser caps on the battery in the background. I don't imagine that they are compatible with your temperature probe.Anawa said:Here's a better close-up of the wiring connection.

--vtMaps

4 X 235watt Samsung, Midnite ePanel, Outback VFX3524 FM60 & mate, 4 Interstate L16, trimetric, Honda eu2000i

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed