Connecting 2 three phase motor to an offgrid system.

enersonsolar

Registered Users Posts: 1 ✭

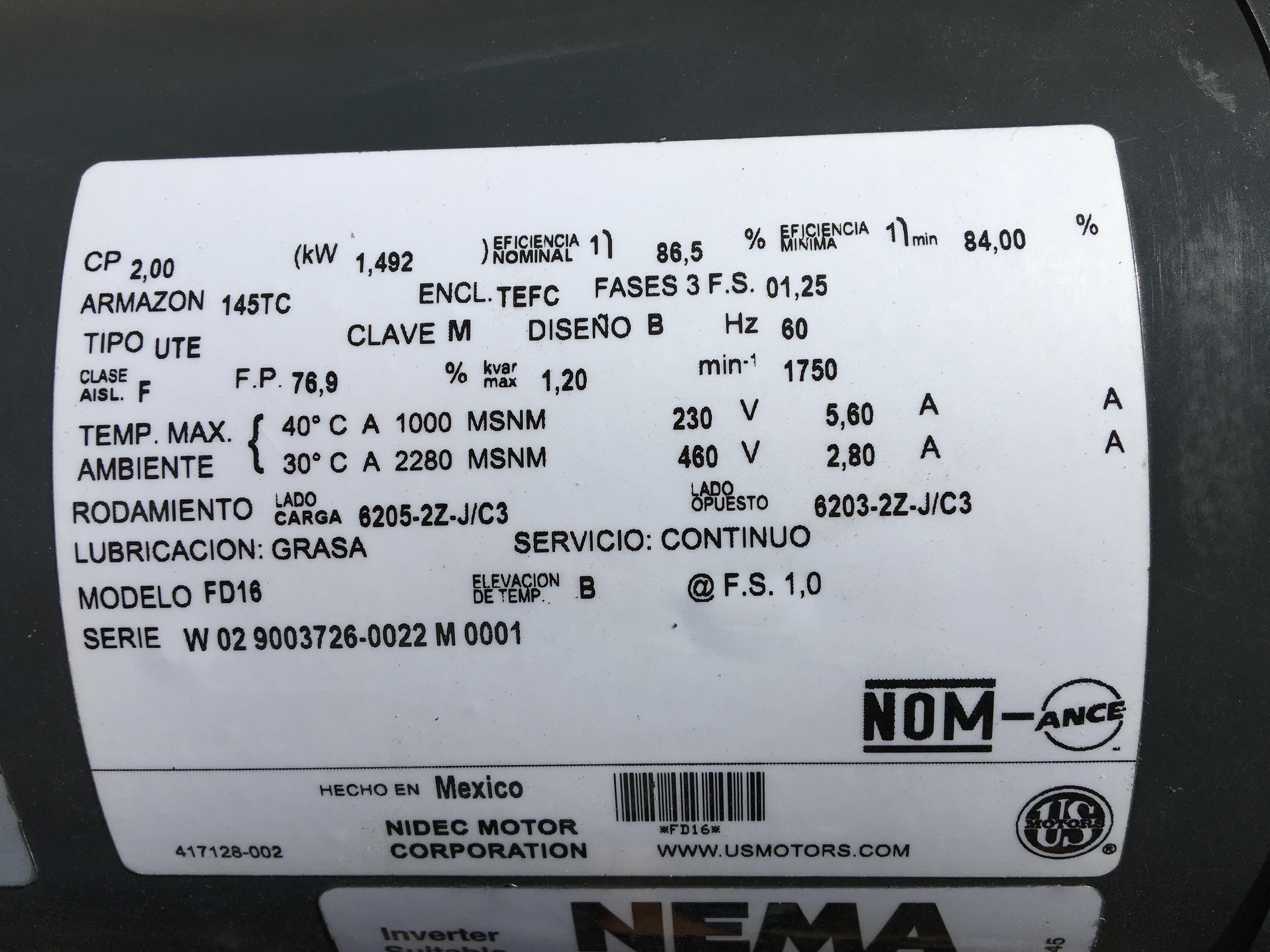

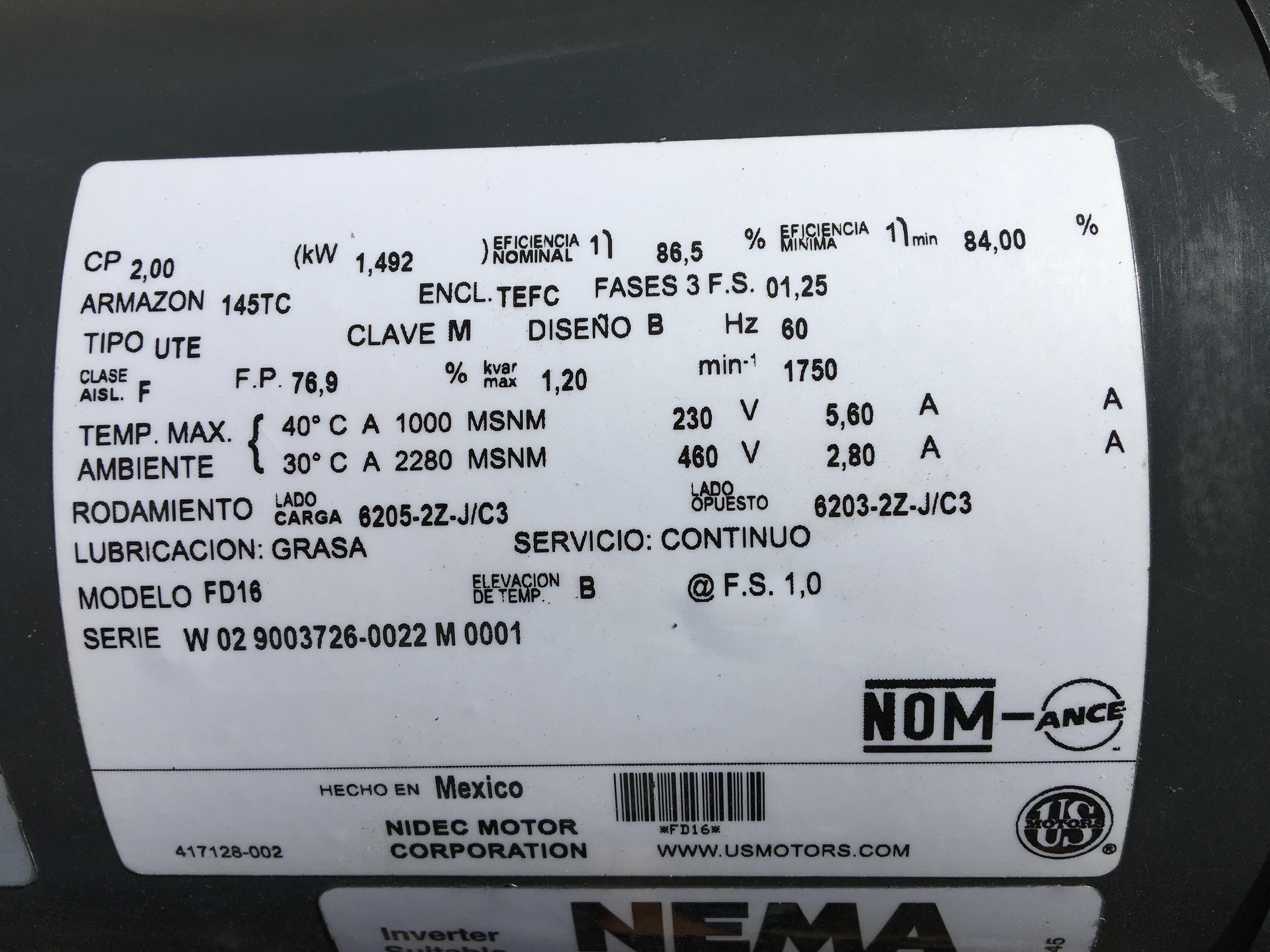

Hi guys, I sell PV systems in Sonora, and up until now, I've never quoted a three phase offgrid system, so I'm a bit confused. This is a packaging plant, they made the investment but the power company won't supply them with the service, so the only ways to go are a diesel plant or an offgrid pv system. It consist on 2 electric motors and some power to run a pc and some office equipment, I'm uploading the motors specifications:

These need to run for 8 hrs a day, starting at 8:00AM with a lunch break at 1:00PM. I ran some numbers, and according to my calculations:

The 2 HP motor, at 230 V has a starting amp of 53.19 and at 460 V 26.6 A

The 1 HP motor, at 230 V has a starting amp of 26.6 and at 460 V 13.30 A

I'm guessing I can use an Outback Power FlexPower Three, but then I have around 9 kW, isn't it too much? Other option is ReneSola, they have these inverters: http://goo.gl/1PrrKT but it says it works at 360 VAC.

Anyway, I get confused, and I hope you guys can give me a hand and suggestions here.

Thanks....

These need to run for 8 hrs a day, starting at 8:00AM with a lunch break at 1:00PM. I ran some numbers, and according to my calculations:

The 2 HP motor, at 230 V has a starting amp of 53.19 and at 460 V 26.6 A

The 1 HP motor, at 230 V has a starting amp of 26.6 and at 460 V 13.30 A

I'm guessing I can use an Outback Power FlexPower Three, but then I have around 9 kW, isn't it too much? Other option is ReneSola, they have these inverters: http://goo.gl/1PrrKT but it says it works at 360 VAC.

Anyway, I get confused, and I hope you guys can give me a hand and suggestions here.

Thanks....

Comments

-

Go with straight 240V electrical service, and buy a couple of Variable Frequency Drive Controllers (VFD) to chop the Grid power up into 3 phase power for the motors. About $300 each. Have a local electrical engineer help you with them.

https://en.wikipedia.org/wiki/Variable-frequency_drive

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

What are the motors going to be used for (Water pumping, running machinery, etc.)?

There are other ways of using three phase motors--There are "starters" that have a relay and starting capacitor to get the motor spinning, then the motor continues on single phase (at less output power).

You can also start a larger three phase motor (capacitor, even use a small motor to get the 3 phase motor spinning--I have even used a rope starter, just like a lawn motor starting) and then you connect a second (or more) three phase motor to the already running motor--Which generates (sort of OK) three phase power. Setup and ran an entire machine shop in a 2 car garage with 120/240 VAC single phase power (from manual Bridgeport mills, to CNC Clausing lathes.

The big issue is that large motors (typically three phase) use a lot of power--and that requires a very large solar array + battery bank (and maintenance). There are some off grid inverters that can be connected together to make three phase power too--But you are usually talking about some very large off grid power systems (12 kW or larger?).

As Mike said--If you can use VFD's -- Those will usually be a very nice solution... Beware that most VFDs (I think) are square wave AC inverters and can cause attached three phase motors to have a shorter life (motors run hotter, more wasted energy with square wave AC drive).

-Bill

Near San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

why wouldn't you just change the motors out to single phase motors? Those frame #s are very common. fwiw

Still

18- 235 W Kyocera panel, 12- 4-KS-25PS Rolls 1350 Ah, Magnum MS4448PAE, ME RC50, ME AGS, Outback FM 80, Generac 8KW LP generator, 6.5 Honda Portable generator -

If you have 3 phase power or converters, there is much more torque, starting is easier.stillchillin said: why wouldn't you just change the motors out to single phase motors? Those frame #s are very common. fwiw Still

Powerfab top of pole PV mount | Listeroid 6/1 w/st5 gen head | XW6048 inverter/chgr | Iota 48V/15A charger | Morningstar 60A MPPT | 48V, 800A NiFe Battery (in series)| 15, Evergreen 205w "12V" PV array on pole | Midnight ePanel | Grundfos 10 SO5-9 with 3 wire Franklin Electric motor (1/2hp 240V 1ph ) on a timer for 3 hr noontime run - Runs off PV ||

|| Midnight Classic 200 | 10, Evergreen 200w in a 160VOC array ||

|| VEC1093 12V Charger | Maha C401 aa/aaa Charger | SureSine | Sunsaver MPPT 15A

solar: http://tinyurl.com/LMR-Solar

gen: http://tinyurl.com/LMR-Lister , -

null

If you want to run this motor on solar then you should use VFD. This solution is very ecnomical and smooth in operation. I have run the water pumps up to 30 hp with no difficulty. -

I never got a mesage telling me I had some replies.

First of all thanks.

Regarding this installation, this are for a customer, they will run machinery in a fresh produce processing plant.

As you can see, they a 1 HP and 1.5 HP motors.

My concern is the starting power (peak power?), according to the numbers I ran, the 2HP Motor has a starting power of 6440W and the other one 3450.

My idea is to buy a 10 kW inverter and install 4.2 kWh ReneSola panels with 8 Surrete 550 Ah 6 volt bateries configured at 48V and a 80A Outback controller.

The larger inverter is for the power peaks when the motors start.

Also, they will work for 8 hrs during the daytime.

What do you guys think? -

Mike 95490 and Syedbukhari gave good answers.

Here is some more info on VFDs.

A three phase motor run by a VFD has no starting surge.

In fact it is actually a reverse surge.

The motor starts turning a 0 amps (or at least what you can see with an amp clamp).

The current ramps up as the RPM increases.

With motors in the 1 Hp range you will usually see a 20% increase in efficiency compared to a single phase motor.

My shop uses a 5 Hp compressor with VFD that runs from solar.

I usually leave it set at 25 cycles.

It just ticks away nice and quiet and draws about one third the power.

If we need the air we turn it up to 60 cycles.

But another advantage for running it slow is cold starts.

On cold nights when it does not run, the oil will set up.

If you try to spin it up to full rpm right away it will kick out the breaker (or pull down the inverter).

But it will start and run just fine when set at low rpm.

18 Kw PV; 2000 AHr FLA Bat; 12 Kw Inverter; 20 Kw Kohler, LP, low speed, double muffled, Home built, ground coupled heat pump, VFD enabled; Leaf

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed