Anyone used a soft start kit for AC motor?

Anyone have hands-on experience with “soft start” kits for 230/1/60

motors? I did a lot of work with 480/3/60 VFDs

many years ago, but I am looking at low-cost options.

Micro-Air has a very good reputation in the RV world when used on smaller rooftop units with undersized generators. Lots of before and after success stories. I recall a customer who used one on his well pump that would stall his genset prior to installing the kit. Unfortunately, I did not get hard numbers and he has since passed away.

Micro-Air tosses out a number like “Up to a 75%” reduction of LRA. Heck, even a 50% to 60% reduction would be a huge benefit in terms of generator usability, especially "conventional" generators. I have asked Micro-Air for more specific info, but they aren’t answering my questions about

how I can estimate it.

Marc

Comments

-

In case anyone wants to know, Micro-Air got back to me after my third request. I used my own 3-ton condensing unit rated 70 amps LRA."Easy Start will reduce in-rush amps by 50-70% for residential units. Anything in that range is what we expect."Their largest unit will handle a 5-6 HP air compressor/pump or an equivalent 6 ton A/C unit. It ain't cheap at $ 350. but it might be worth it in some applications. Running a small central A/C unit or well pump on a conventional portable generator could be interesting. I have no idea of what happens to PF, so the picture could change.

.

I always have more questions than answers. That's the nature of life. -

For offgrid we would never use something that big/old. Much better to use mini-splits! All of them will run off a small/medium genset.

Even for grid homes, a small split in the mix is nice as you can cool/heat down part of a house. In Texas/Florida on a small battery based system, or a genset, will make it automatic with a critical load panel.

It is kind of a doomsday approach but recent history has not been kind to people on the grid. If it is important to folks to not have the problems of loss of power, there are easy ways to avoid the pain. Just add money "we go where power lines don't" Sierra Nevada mountain area

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Something like this is what I need for my sewage grinder pump. It only runs a couple of minutes/day and running load is about 800 W, but the startup is killer. They recommend a 6500 W generator.I have a grid tied system and the grid is very reliable here, but occasionally I dream about battery backup.

-

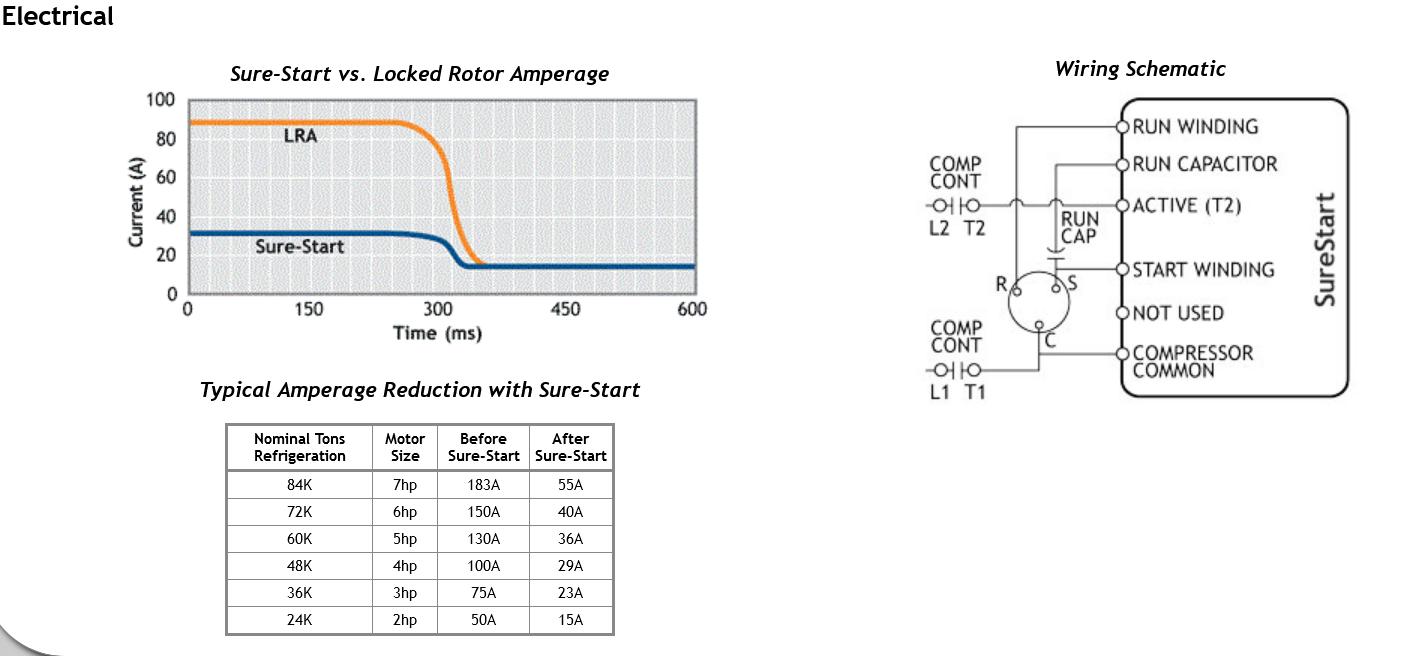

Hyper Technology makes a "Hyper sure start" for hvac compressors, their site also shows a special order for well pump application. The hvac versions are in the + - $250 range, some are listed on ebay. These are soft start and not a hard start. They show some good specs and info in their installation manual download.

-

I was going to suggest looking for a 3 phase grinder pump with a VFD (variable frequency drive)... But those things are 2 HP and up, and >$2,000 or so.

Does not look cost effective--Unless no other option for solar.

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Bill if you or one of the very knowledgable could check the Hyper Sure start specs I think some of the members would be interested. I used one but had no means to check inrush. Thanks

-

Dave Angelini said:For offgrid we would never use something that big/old. Much better to use mini-splits! All of them will run off a small/medium genset.

Even for grid homes, a small split in the mix is nice as you can cool/heat down part of a house. In Texas/Florida on a small battery based system, or a genset, will make it automatic with a critical load panel.

It is kind of a doomsday approach but recent history has not been kind to people on the grid. If it is important to folks to not have the problems of loss of power, there are easy ways to avoid the pain. Just add money Yes, Sir. I carried a C20 license and was an HVAC system designer in CA for 10 years

Yes, Sir. I carried a C20 license and was an HVAC system designer in CA for 10 years If I were starting over, I would look at mini-splits specifically for the hunker-down mode advantages. It wouldn't pay to change now because my system is efficient and already zoned to let me go down to 40% of the house without the usual negative impacts. At $0.095/kWH with no TOU or demand charges, it's tough to justify major items on a strictly financial basis - until something breaks!A combination of design elements allows me to hold 73F @ our normal peak 95F ambient in all 2500 sq ft with a 3 ton system. (Do the math!) Could mini splits do the same or better? Yes, that is why I often recommend them to people.I always have more questions than answers. That's the nature of life.

If I were starting over, I would look at mini-splits specifically for the hunker-down mode advantages. It wouldn't pay to change now because my system is efficient and already zoned to let me go down to 40% of the house without the usual negative impacts. At $0.095/kWH with no TOU or demand charges, it's tough to justify major items on a strictly financial basis - until something breaks!A combination of design elements allows me to hold 73F @ our normal peak 95F ambient in all 2500 sq ft with a 3 ton system. (Do the math!) Could mini splits do the same or better? Yes, that is why I often recommend them to people.I always have more questions than answers. That's the nature of life. -

I looked at the Hyper Sure Start as suggested by Wayne. Now I wonder if I can start my condensing unit with my conventional Honda 5000 watt generator. Same with the lake water fire pump.

I always have more questions than answers. That's the nature of life.

I always have more questions than answers. That's the nature of life. -

I have to go... But here are some links:

https://eltwin-hyper.com/single_phase.html (home page for single phase)

https://eltwin-hyper.com/literature/SC5600HM-SureStart-Specification-Catalog.pdf (white paper on unit)

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Dave Angelini said:For offgrid we would never use something that big/old. Much better to use mini-splits! All of them will run off a small/medium genset.

The 1 ton inverter based mini splits will run off of a Honda 2000. A friend of mine down here added pigtails and transfer switches to hers to keep her battery bank from over discharging overnight.2.1 Kw Suntech 175 mono, Classic 200, Trace SW 4024 ( 15 years old but brand new out of sealed factory box Jan. 2015), Bogart Tri-metric, 460 Ah. 24 volt LiFePo4 battery bank. Plenty of Baja Sea of Cortez sunshine.

-

A friend who is a female

The other thing about soft start circuits on old/big compressors is they have been known to damage their loads. I have the stories with over 500+ homes now !

In a way, it forces the owner to modernize. I certainly would not want to change out a sewage pump before it's time "we go where power lines don't" Sierra Nevada mountain area

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Dave, experience is what I was asking for. So, you are saying that you have seen these soft start kits damage compressors, more than rarely? I feel that hard start kits are rough on them, but I had the opposite impression of soft start. Mine is only a few months old.Dave Angelini said:A friend who is a female

The other thing about soft start circuits on old/big compressors is they have been known to damage their loads. I have the stories with over 500+ homes now !

In a way, it forces the owner to modernize. I certainly would not want to change out a sewage pump before it's time Thanks!I always have more questions than answers. That's the nature of life.

Thanks!I always have more questions than answers. That's the nature of life. -

I would get guidance from the manufacturer. When a compressor motor or pump motor is designed, it often is based on experience.

If the Engineers thought it would not be a problem to soft start, they should tell you. Looking in the warranty is always a good place to look if the company is not being helpful.

I do not know what a "hard start kit" is BTW? Typo?"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

Hard Start (aka Fast Start) is a capacitor-based system to give the compressor a kick to help it spin up faster. Some are more complex than others but because part of the inrush surge is carried by the kit, they are sometimes used for A/C on generator duty. They used to be available as a factory option for unusual field conditions. I am not a fan of them except as a means of squeaking another year or two out of an old unit or dealing with a deficiency of an undersized long wiring run - or compressor problems.It seems that the Soft Start kits reduce the actual peak inrush current instead of just the time. With a combination of Triacs, caps, and a self-tuning algorithm for optimization. I suspect that the start time is extended somewhat but at a very low current. These have no impact on Carrier scroll compressor warranty when installed by a certified tech. No reason to include them from the factory because they are not needed for normal residential installations.Again, my past experience was with lots of large three-phase compressors/motors using VFD's. I have ZERO experience with these little units for small motors!I always have more questions than answers. That's the nature of life.

-

OK that is what I call a 3 wire motor but it is not a "kit". It is designed in by the manufacture like a Franklin deep well water pump with the capacitor JB at the top of the well, for instance.

I still would look at the AC warranty. A good company will tell you how they will void your warranty. They might even tell you what they think of your idea if you ask them. Adding a vfd does seem like a way for both companies to blame the other when things go south.

For offgrid, doing things like adding circuitry to a known good system is a reliability issue. We want a Hi-Rel power/load system !

Anything short of that means more spares. To me, it voids the less is more mantra of good engineering.

"we go where power lines don't" Sierra Nevada mountain area

htps://offgridsolar1.com/

E-mail offgridsolar@sti.net -

If you do use a VFD... There are "inverter rated" induction motors that are designed to have a longer life when used on a VFD (1,500 VAC rated vs 600 volt rated windings and such). A standard VFD is more of a MSW (modified square wave) which can generate higher voltage peaks vs sine wave (utility) power:

https://www.precision-elec.com/faq-vfds-should-i-use-an-inverted-rated-motor-on-vfd-applications/

Which is what a machinest friend of mine saw--VFD equipped (typically 3 phase in his case) often failed in a few years.

The Sure Start--More or less, the require the induction motor to have zero load (fan, pumps that don't have head/back pressure, etc.). The Soft Starts reduce starting torque and may not start motors that require "non-zero" starting torque (basically compressor systems that "balance" or bleed off pressure between pump input and output):

gen-pro.biz/faqMore or less, induction motor torque is proportional to input current. Reduce input "starting" current, reduce starting torque.Can I apply SureStart to well pumps or other applications?

Although no significant testing has been done, well pump applications have had SureStart applied successfully. Please review the requirements for reciprocating/rotary compressors as they pertain to starting "under a load." SureStart is designed to start direct, across-the-line motor starts that have ZERO load applied on the motor shaft. If there is a load on the compressor or pump motor at startup, SureStart should not be applied.

Compressor motor RLA considerations are also necessary to verify potential operation.SureStart should not be applied to "squirrel-cage" or other types of fans.

I am surprised to not use SureStart on squirrel cage and other types of fans... Perhaps those already have low starting torque motors and reducing starting current even more does not help (longer time to spin up fan?)?

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

And a youtube video or two.

Here is an install on a 20+ year old central air compressor system. Note that the Fluke did not "catch" the inrush current. And the max hold on the other meter may not (in my humble opinion) catch the true starting current either: https://www.youtube.com/watch?v=FcmCo8HfP38

https://www.youtube.com/watch?v=FcmCo8HfP38

And a commentate copied from the literature on how it functions in the system:That 1 second start window--May explain why large squirrel cage fans may not start correction (may take a few seconds to get up to speed.From Hyper Engineering Literature

SureStart Operation When the system control calls for compressor operation, the compressor contactor will energize. If the supply voltage to the SureStart is less than “Minimum Startup Voltage”, a 50 second delay is initiated. At the end of the delay, another attempt to start the compressor will begin unless the supply voltage remains unchanged. SureStart uses an optimized starting process that learns the starting characteristics of the compressor to further refine the starting cycle on each recurring start.

If the compressor fails to start, the module will terminate the start attempt after 1 second and initiate a 3 minute lockout before attempting a restart. If the supply voltage falls below “Shutdown on Low voltage” limit for 2 seconds or below 130 volts for 0.1 seconds while the compressor is running the module will stop the compressor and initiate a 3 minute lockout. A restart will be attempted after 3 minutes

if the supply voltage is equal to “Minimum Startup Voltage” or higher. This is done to protect the compressor against a sudden drop in supply voltage. SureStart is able to detect an interruption in power, when the interruption is 0.1 seconds or longer. When a power interrupt is detected, SureStart will shut down the compressor for 3 minutes.

SureStart is also able to determine if the compressor is running backwards. If this condition is detected, SureStart will stop the compressor for 3 minutes before a restart is attempted. A power interrupt that is shorter duration than 0.1 seconds may result in a compressor running backwards, which the SureStart can detect and stop compressor operation.

If the run capacitor is faulty or has failed, SureStart will shutdown the compressor for 3 minutes before attempting a restart.

Two Honda eu2000i + 5kWatt 120/240 VAC transformer with SureStart: https://www.youtube.com/watch?v=lhgtbuV5RYI

https://www.youtube.com/watch?v=lhgtbuV5RYI

And running a Predator brand 3,500 inverter-Genset+transformer with general house loads: https://www.youtube.com/watch?v=IcZyxV7Mezs

https://www.youtube.com/watch?v=IcZyxV7Mezs

Anyway... Some simple demonstrations.

-Bill

Note: Predator was overloaded on starting...Near San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

I've been using a hyper sure start on my 1.5 ton lennox unit since probably 2014ish. IIRC dropped startup amps from ~35-40 to 6. I had to replace the hyper two years ago as it died. It hasn't created any problems with the AC unit.

-

jtdiesel65 said:I've been using a hyper sure start on my 1.5 ton lennox unit since probably 2014ish. IIRC dropped startup amps from ~35-40 to 6. I had to replace the hyper two years ago as it died. It hasn't created any problems with the AC unit.

Thank you, Sir.

I always have more questions than answers. That's the nature of life. -

Marc Kurth said:jtdiesel65 said:I've been using a hyper sure start on my 1.5 ton lennox unit since probably 2014ish. IIRC dropped startup amps from ~35-40 to 6. I had to replace the hyper two years ago as it died. It hasn't created any problems with the AC unit.

Thank you, Sir.surehere is actual measurements

-

Again, I thank you for the info. Since I started this thread, I have gotten input from other users with very positive feedback. Three of them are off-grid customers, and two are HVAC contractors who regularly install these. My 10 year warranty stays intact if it is installed by a certified Tech.Since I already own a Honda 5000 watt generator and a 3-ton heat pump, spending $268.00 to make them work together is valuable to me for occasional emergency operation. (The Honda will support 7000 watts for 10 seconds)

I always have more questions than answers. That's the nature of life. -

No problem.

Start your own thread (keep Marc's thread clean). Suggest you use Private Messages to exchange personal information.

-Bill "moderator" B.Near San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Thanks Bill will do so.

-

Hardstart + softstart units like Easystart, SureStart, SecureStart, and SoftstartRV work well for air conditions and other induction motors that use just a smaller value run capacitor. They combine the hardstart large value cap with voltage ramp softstarter. Normal startup time for air conditioner compressor is 0.4 to 0.5 seconds. The run capacitor alone provides minimal startup rotational torque but improves motor run power factor.

High starting load torque induction motors, like water pumps and air compressors do not improve by as much when trying to start from an inverter. These motor applications already have a large value start capacitor with centrifugal switch to disengage start cap. They usually don't have an additional run capacitor since they are used for short run times where improving power factor is not as important. The softstarter function alone on these hardstart + softstart units only provides voltage ramping for these motors. It reduces startup current somewhat but startup period last longer which usually exceeds time inverter can tolerate the overload.

For air conditioners, the outside unit fan must not be put on softstarter output. Fan immediately comes on when original contactor is engaged. This provides a load to keep inverter out of sleep mode and inverter-generator out of reduced rpm ECO mode so they have full power available for upcoming compressor startup. The softstart controller has several seconds of delay before it begins softstart ramp to ensure an inverter-generator is up to full rpm speed before compressor startup is attempted.

When first installed, these softstarters go through a self training process for the first five or six turn-on activations to find the best voltage ramp to achieve best current reduction while still achieving reliable startup for a given motor. It is recommended the training be done on utility grid power to prevent training being compromised by a slumping voltage of inverter or inverter-generator.

If softstarter is moved to another air conditioner its memory must be reset to factory default state so it begins a new training sequence for the different compressor motor. The manual should tell you how to do this, or may require a call to manf. service to get instructions how to reset softstarter.

-

Great writeup with clear explanations! You clarified some questions that I had not invested the time to research.I thank you for your effort.I always have more questions than answers. That's the nature of life.

-

I tried brands EasyStart and SureStart on a York 3 Ton Heat Pump this year that my High Voltage, High Frequency Hybrid 6kw inverter couldn't handle and found that they would reduce the inrush, but not nearly enough for the inverter. Stock, inrush was about 85 amps, with the Surestart was the better on reducing to about 55 amps, other was about 62 amps ( and I have a meter for specifically measuring this ).

My solution was to install a ducted mini-split heat pump ( MrCool / Gree ), they are inverter based and have no surge to speak off, are 20 SEER to boot and work to -22F, so no resistance heat strips needed. The York, while still running well was 13+ years in service. The mini-splits can be bought without the markup of local installers or need for communicating thermostats. Yes, not the most cost efficient solution, but the HF inverters compared to LF we know and well cost difference covered all the costs.

Categories

- All Categories

- 233 Forum & Website

- 141 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 900 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed