wiring a 48v bank with 9 strings of 12V

Brody711

Registered Users Posts: 5 ✭✭

Hello all

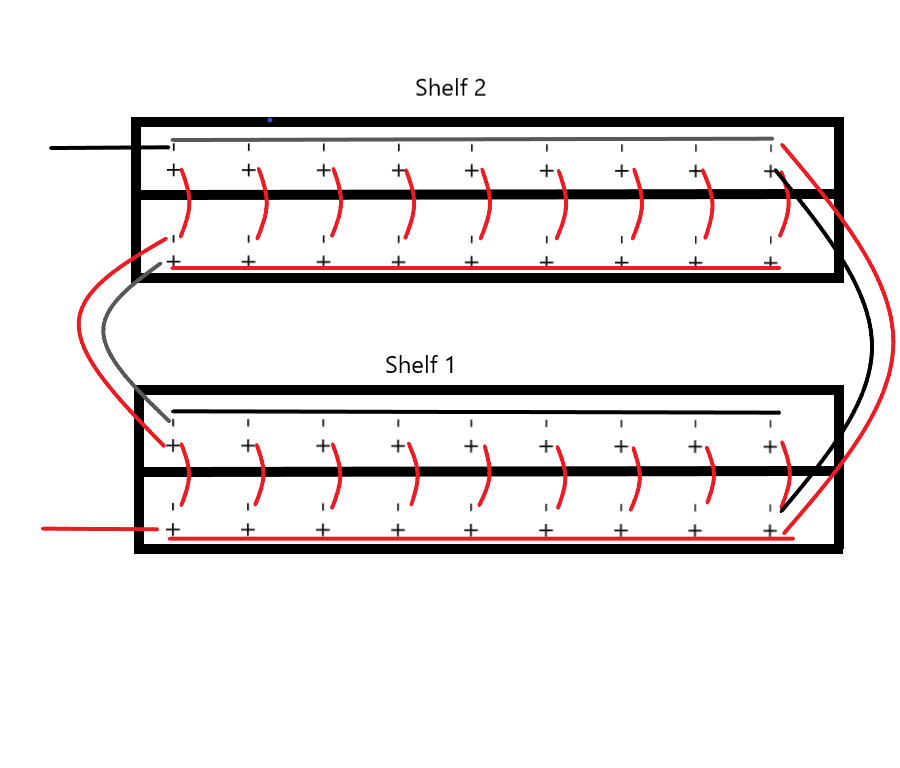

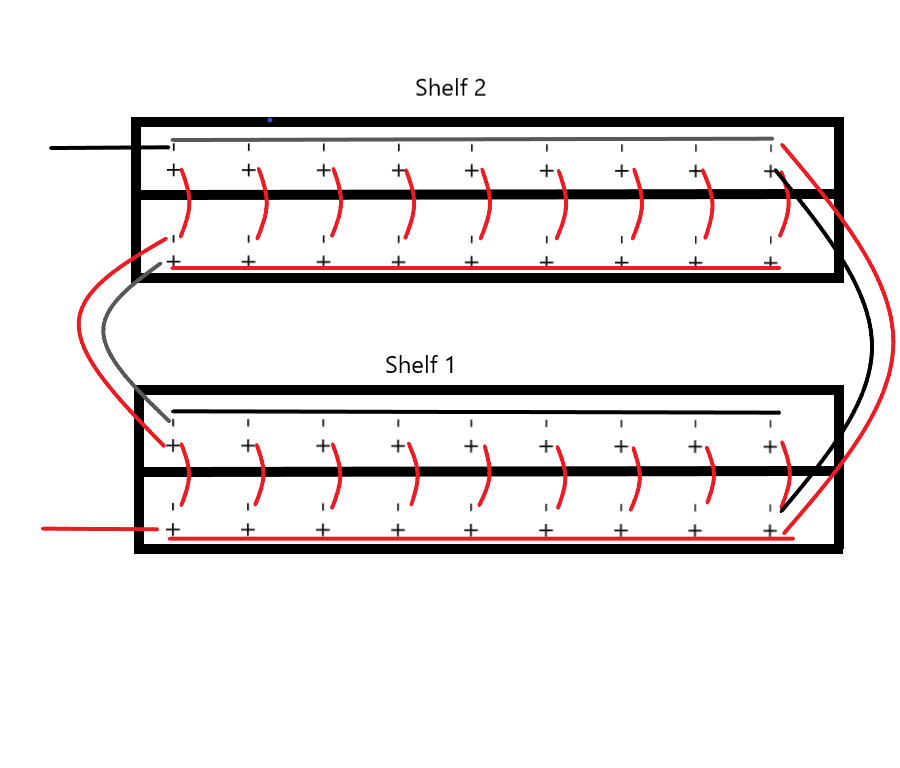

I have a question regarding the correct way to wire up my batteries for the 48V bank i need. I have 2 shelves that allow me to set two 12v batteries next to Each other wired in series/parallel. I can have 9 deep with a total of 18 per shelf. My question is connecting the lower shelf to the upper shelf to get the 48V bank. I want to make sure i am pulling from the correct end on my configuration. I have buss bars to use as well. I have looked at battery wire diagrams etc and have a way i think to have it done but want to check with the crowed for input first. . Batteries are 12v 88AH the bank i am trying to achieve is 48V 792AH. Also i would like to know the best locations for my terminal fuses for the batteries. Thanks for any suggestions on how to wire my 48v Bank with my racking i have

I have a question regarding the correct way to wire up my batteries for the 48V bank i need. I have 2 shelves that allow me to set two 12v batteries next to Each other wired in series/parallel. I can have 9 deep with a total of 18 per shelf. My question is connecting the lower shelf to the upper shelf to get the 48V bank. I want to make sure i am pulling from the correct end on my configuration. I have buss bars to use as well. I have looked at battery wire diagrams etc and have a way i think to have it done but want to check with the crowed for input first. . Batteries are 12v 88AH the bank i am trying to achieve is 48V 792AH. Also i would like to know the best locations for my terminal fuses for the batteries. Thanks for any suggestions on how to wire my 48v Bank with my racking i have

Comments

-

I am not sure what is going on with your drawing... I fear that you are creating one or more dead shorts across the 12 volt segments.

Here is a good website that suggests different methods of wiring to achieve "balanced" charging and discharging of paralleled battery strings.

http://smartgauge.co.uk/batt_con.html

I like #3 as it is simple and clear what you are doing. Also, you can fuse each battery string for safety. (for example, 4 parallel strings, then 4 fuses needed). Other wiring methods make fusing much more difficult/expensive.

Can we go back to exactly what batteries you are using (Flooded Cell Lead Acid, AGM, Lithium Ion, etc.)?

My personal suggestion is a bunch of 12 volt @ 88 AH batteries is a really poor choice for your system--Some folks can get XX by YY batteries for free from UPS/Telecom systems... But this is frequently not worth the time/other costs to do.

If you put 4x of your 12 volt batteries in series, you get 48 volts... Put 9x of your 48 volt strings in parallel, you get your 792 AH (and your 48 volt @ 792 AH battery bank).

My humble suggestion is you should be looking at 1-3 parallel strings of batteries. That means you need larger AH batteries... For example, say you use 6 volt @ 200 AH batteries.. That would be a 8x series (8x 6 volts = 48 volts) by 4x parallel strings (4x 200 AH = 800 AH).

Or you can even find 4 or 2 volt batteries (technically 4 volts is 2x cells, and 2 volt is a "cell"--Batteries are 2 or more cells integrated into one unit).

Other batteries you could look at (just for example--Your needs are your needs--And details matter here). The below is just an example of what is out there--No idea what your actual needs are:

https://www.solar-electric.com/trl16vo225ah.htmlL16P 6 Volt, 420 AH Deep Cycle Battery

That would be 4x 6 volt in series and 2x 420 AH parallel strings for a 48 volt @ 840 AH battery bank (very nice).

https://www.solar-electric.com/tr897am6vode.htmlTrojan 897 Amp-hour 6 Volt Deep Cycle Battery

That would be 4x 6 volt @ 897 AH batteries in series--Just one series string, and you are done.

There can be lots of issues... Lead Acid batteries are heavy, need access to water (if flooded cell), etc... But it is (in the end) much easier to wire up 1-3 parallel strings of batteries than to try and setup 9 parallel strings of batteries.

I highly suggest that you not try to make a large battery bank out of 12 volt @ 88 AH batteries... If nothing else (if money is an issue), I would start with a 4x series by 4x parallel strings of 6 volt @ ~ 200 AH batteries. That is still 24x "golf cart" batteries at (something like) $100 each... But with good maintenance, should last much longer than 88 AH batteries.

And exactly what 12 volt @ 88 AH batteries are you looking at? Typically the "free/lost cost" batteries are for UPS/battery backup systems... Frequently, you may get 10's to 100's of cycles from them before then "die". Usually these are batteries designed for "float" service--Just sitting under charge until there is a power failure.

True deep cycle batteries should give you several thousands of cycles before they "wear out".

Regarding racking--In general, you do need to be able to safely access batteries once a month of inspection (and maintenance if flooded cell batteries--Need to check electrolyte levels, add distilled water 3-12x per year)... If you cannot safely/easily access some of the batterieds, they will not get serviced and will be killed relatively quickly (FLA batteries need to be watered something like every 1-6 months with distilled water--Running batteries with exposed plates will quickly kill them).

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Yes the drawing was wonky the only thing I could find that had the amount of batteries I have.

I already have 36 VRLA batteries they are VRS 12-88HIT Solar batteries I know there are many other options out there for batteries. They were new from a company that went out of business I purchased for $1 an AH. . But given that I already have the batteries I would like to wire them to achieve 48v which I understand how if they were all on a single level My question was they will be on a rack so half on one shelf the rest on the other.

Is it possible to wire them to 48V being on 2 shelves.

Thanks -

Poster 2manytoyz has a lot of about his DIY solar system over the years... With lots of pictures.

One method would be to put 4x batteries in series. Then run a + and - lead from each string of batteires to a common copper bus bar.

http://2manytoyz.com/battbank.html

The idea is to keep each wiring path the same length so that each battery string "sees the same wiring resistance" to the bus bars.

The actual cable length is not usually an issue (say 2 feet for + and 5 feet for negative on one string, and 5 feet on + and 2 feet on a second battery string does not change things... The fact that the total wiring is 7 feet (in this example) between each string and set of bus bars is what is important.

You have AGM batteries--With a very good rated cycling life--That is good. Make sure that the batteries are all charged, and to the same level. AGM batteries can go upwards of 6 months (typical) between charging (batteries stored in hot climates, need charging more often). So--Keeping them charged helps reduce sulfation (batteries stored at less than ~75% SoC sulfate much faster) is one issue.

The other is that the batteries need to be at the same state of charge (especially each group of 4x batteries in series need to match SoC). AGM batteries keep their balanced state of charge pretty well--And they do not like "equalization current" (basically over charging some batteries in series to bring up weak batteries in the same string).

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

Awesome. would you see a problem with the cable lengths below for each string if they were all the same? I just want to make sure i can use a longer cable to connect the bottom shelf to the top. if i can then problem solved. Thanks

B1 B2 B3 B4

3' to Pos + - 6" + - 18" + - 6" + - 3' to Neg -

Looks OK... In general, keeping things short for low voltage DC is good. And heavy enough cable to carry the current.

Then comes the assumptions and the math... Lets say that you have 88 AH AGM type batteries and will draw C/2.5 rate. And you want around 2 volt maximum wiring drop @ 48 VDC. And you have ~4.5 feet of cable (one way run for this voltage drop calculator)... The math would be something like:a- C/2.5 rate of discharge = 88 AH / 2.5 = 35 Amp max draw (in theory, 2.5 hour current from 100% to 0% state of charge)

https://lugsdirect.com/WireCurrentAmpacitiesNEC-Table-301-16.htm

The NEC table is relatively conservative (the actual NEC book has a lot more variables--conduit fill, ambient temperature, etc.)...

And I like to use an 0.80 (or 1.25x) factor for off grid battery systems. NEC derating for continuous loads (like charging the battery bank for hours, or discharging into an Inverter for hours, etc.):- 35 Amps * 1.25 NEC derating = 44 Amps suggested branch wiring/fuse/breaker rating

Now voltage drop... 35 Amps, 4.5 feet one way wire run, and 2 volt max drop at 48 volts:

https://www.calculator.net/voltage-drop-calculator.html?material=copper&wiresize=2.061&voltage=48&phase=dc&noofconductor=1&distance=4.5&distanceunit=feet&eres=35&x=57&y=23

Using 8 AWG wiring:

Voltage drop: 0.20

Voltage drop percentage: 0.41%

Voltage at the end: 47.8

https://www.calculator.net/voltage-drop-calculator.html?material=copper&wiresize=1.296&voltage=48&phase=dc&noofconductor=1&distance=4.5&distanceunit=feet&eres=35&x=56&y=28

Using 6 AWG wiring:

Voltage drop: 0.12

Voltage drop percentage: 0.26%

Voltage at the end: 47.83

Assuming 35 amps from 9x parallel battery strings:- 35 amps * 42 volts battery cutoff for inverter * 0.85 AC inverter eff * 9 battery strings = 11,246 Watt AC inverter output (maximum)

- 88 AH * 1/20 hour rate = 4.4 amps per battery string

- 4.4 amps per string * 9 parallel strings * 42 volts battery cutoff * 0.85 AC inverter eff = 1,414 Watt "average" suggested output

- 88 AH * 1/8 hour rate = 11 amps per battery string

- 11 amps per string * 9 parallel strings * 42 volts battery cutoff * 0.85 AC inverter eff = 3,534 Watt "maximum" suggested continuous load

Assuming 35 Amps from each battery string is quite a large draw from those Batteries... In general, you would really only plan on 11 Amps per string max for a conservative/typical operational profile on batteries.

And we have not talked about charging current... Many AGM batteries can take >C/8 charging current, so you need to validate your wiring size based on maximum charging current too. Using C/2.5 or 35 Amp draw/charge is very conservative for wiring requirements (gives you relatively heavy cables)--And would probably do anything you would do with that size/configuration of batteries.

Remember too, that you have cables from the battery combiner to the AC inverter / Charger. And fuses/breakers do have voltage drops too (I suggest a maximum 2 volt drop for entire wiring from battery to bus to inverter/etc. And you have to size the inverter/charger/etc. wiring branch circuits too). And a typical AC inverter can support 2x rated output surge current too for a few seconds--So you do not want too small of cable/too much voltage drop if you have surging loads (well pump, induction motors, etc.).

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset -

I know of someone who has a Battery Bank much like the attached PDF.Brody711 said:Awesome. would you see a problem with the cable lengths below for each string if they were all the same? I just want to make sure i can use a longer cable to connect the bottom shelf to the top. if i can then problem solved. Thanks

B1 B2 B3 B4

3' to Pos + - 6" + - 18" + - 6" + - 3' to Neg

I has been working well for 3 years, now

The deviation in the specific gravity readings in all of the cells, in every battery, is still very small.

There is an air gap around every battery

The interconnect cables between the batteries are as short as possible

Each SET of 9 cables were made as identical, as possible.

The Copper Bus Bars are much shorter that shown - not to scale - the bolted connection are literally adjacent to each other

The cables from the Copper Bus Bar to the battery bank are much longer than shown - not to scale.

If you can repeat the same cable ... 9 times, then this can be done and it can be successful.

The Charge Controller wires and the Load +/- wires connect to the Buss Bars only,

they do not get connected to any Battery Terminal.

You need to insert fuses, as needed.

Everything must be "100% symmetrical", as humanly possible, for this work ...

-

BB. said:Looks OK... In general, keeping things short for low voltage DC is good. And heavy enough cable to carry the current.

Then comes the assumptions and the math... Lets say that you have 88 AH AGM type batteries and will draw C/2.5 rate. And you want around 2 volt maximum wiring drop @ 48 VDC. And you have ~4.5 feet of cable (one way run for this voltage drop calculator)... The math would be something like:a- C/2.5 rate of discharge = 88 AH / 2.5 = 35 Amp max draw (in theory, 2.5 hour current from 100% to 0% state of charge)

https://lugsdirect.com/WireCurrentAmpacitiesNEC-Table-301-16.htm

The NEC table is relatively conservative (the actual NEC book has a lot more variables--conduit fill, ambient temperature, etc.)...

And I like to use an 0.80 (or 1.25x) factor for off grid battery systems. NEC derating for continuous loads (like charging the battery bank for hours, or discharging into an Inverter for hours, etc.):- 35 Amps * 1.25 NEC derating = 44 Amps suggested branch wiring/fuse/breaker rating

Now voltage drop... 35 Amps, 4.5 feet one way wire run, and 2 volt max drop at 48 volts:

https://www.calculator.net/voltage-drop-calculator.html?material=copper&wiresize=2.061&voltage=48&phase=dc&noofconductor=1&distance=4.5&distanceunit=feet&eres=35&x=57&y=23

Using 8 AWG wiring:

Voltage drop: 0.20

Voltage drop percentage: 0.41%

Voltage at the end: 47.8

https://www.calculator.net/voltage-drop-calculator.html?material=copper&wiresize=1.296&voltage=48&phase=dc&noofconductor=1&distance=4.5&distanceunit=feet&eres=35&x=56&y=28

Using 6 AWG wiring:

Voltage drop: 0.12

Voltage drop percentage: 0.26%

Voltage at the end: 47.83

Assuming 35 amps from 9x parallel battery strings:- 35 amps * 42 volts battery cutoff for inverter * 0.85 AC inverter eff * 9 battery strings = 11,246 Watt AC inverter output (maximum)

- 88 AH * 1/20 hour rate = 4.4 amps per battery string

- 4.4 amps per string * 9 parallel strings * 42 volts battery cutoff * 0.85 AC inverter eff = 1,414 Watt "average" suggested output

- 88 AH * 1/8 hour rate = 11 amps per battery string

- 11 amps per string * 9 parallel strings * 42 volts battery cutoff * 0.85 AC inverter eff = 3,534 Watt "maximum" suggested continuous load

Assuming 35 Amps from each battery string is quite a large draw from those Batteries... In general, you would really only plan on 11 Amps per string max for a conservative/typical operational profile on batteries.

And we have not talked about charging current... Many AGM batteries can take >C/8 charging current, so you need to validate your wiring size based on maximum charging current too. Using C/2.5 or 35 Amp draw/charge is very conservative for wiring requirements (gives you relatively heavy cables)--And would probably do anything you would do with that size/configuration of batteries.

Remember too, that you have cables from the battery combiner to the AC inverter / Charger. And fuses/breakers do have voltage drops too (I suggest a maximum 2 volt drop for entire wiring from battery to bus to inverter/etc. And you have to size the inverter/charger/etc. wiring branch circuits too). And a typical AC inverter can support 2x rated output surge current too for a few seconds--So you do not want too small of cable/too much voltage drop if you have surging loads (well pump, induction motors, etc.).

-Bill Bill,

Bill,

Awesome! Thank you so much for this reply. I have had many questions on my checklist that when i get to would need some thinking and you did that for me. Saved me time which in this life is limited. I apologize for not having my system details initially as it has been evolving a little as i go. I am using 1/0 wire for cable connections between batteries and from the buss bars to the main breaker/Inverter i was thinking of 2/0? Battery rack/buss bar leads are 10ft away from Main Breaker/Inverter.

My system:

-(10) LG NEon 360W panels https://www.lg.com/us/business/solar-panels/lg-LG360Q1C-A5

Two panels wired in series, 5 strings

-2kw Wind Turbne TESUP https://www.tesup.us/product-page/atlas20-48v-2kw-wind-turbine-generator-for-homes-battery-energy-amazon-usa

-2kw Micro Hydro electric generator ( not yet installed) This is going into my Pumped Hydro set up we are constructing on our farm.

-Eco worthy Combiner

-Midnight 150 classic

-Midnight MNDC Plus box with 175A Main http://www.midnitesolar.com/productPhoto.php?product_ID=235&productCatName=Mini%20%20DC%20Disconnect&productCat_ID=8&sortOrder=11&act=p

-SMA Sunny Island 5048 Inverter I have 3 of these

https://thesolarstore.com/si5048-sunny-island-battery-based-inverter-charger-5000w-48v-p-996.html

-SMA Smart Former https://www.sma-america.com/newsroom/current-news/news-details/news/1429-sma-smartformer-enhances-design-flexibility-of-sunny-island-systems.html

-36 VR Solar Batteries 12v 88 HIT https://www.cdtechno.com/pdf/lit/12_1062_0612.pdf

This system powers our

-200k btu wood pellet boiler pellet duo 60 https://www.mbtek.com/products/copy-of-pellet-duo-25-85000-btu

-Grundfos multi voltage solar water pump that we get 21gpm at 1300w using AC or DC https://thesolarstore.com/grundfos-sqflex-11-sqf-solar-submersible-pump-p-525.html

-refrigerators

-Lights/Security system

-

Thank you for this. looks to be what im going with. Also i have got 175A terminal block fuses for all the leads going to the + buss bar.mvas said:

I know of someone who has a Battery Bank much like the attached PDF.Brody711 said:Awesome. would you see a problem with the cable lengths below for each string if they were all the same? I just want to make sure i can use a longer cable to connect the bottom shelf to the top. if i can then problem solved. Thanks

B1 B2 B3 B4

3' to Pos + - 6" + - 18" + - 6" + - 3' to Neg

I has been working well for 3 years, now

The deviation in the specific gravity readings in all of the cells, in every battery, is still very small.

There is an air gap around every battery

The interconnect cables between the batteries are as short as possible

Each SET of 9 cables were made as identical, as possible.

The Copper Bus Bars are much shorter that shown - not to scale - the bolted connection are literally adjacent to each other

The cables from the Copper Bus Bar to the battery bank are much longer than shown - not to scale.

If you can repeat the same cable ... 9 times, then this can be done and it can be successful.

The Charge Controller wires and the Load +/- wires connect to the Buss Bars only,

they do not get connected to any Battery Terminal.

You need to insert fuses, as needed.

Everything must be "100% symmetrical", as humanly possible, for this work ... -

Regarding your plans for a VAWT--In general, I (personally) am not a fan of wind turbines... They rarely produce anything near the predicted/expected output--And the few that do/did, did not hold up very well.

From what little I have seen, VAWT (Vertical Axis Wind Turbines) have never produced any usable power--Either not very efficient (like this type) and/or tended to fall apart over a relatively short period of time (if they ever got the VAWT to work in the first place).

I would certainly suggest that you measure your local wind conditions, and (typically) plan on a 10 meter / 33 foot minimum tower--And the turbine needs to be above/up wind of any local obstacles (trees, buildings, hills). Also, if you are in a lighting prone area, they tend to attract lightning hits too.

One of the suggestions for VAWT was that they are great for mounting on buildings/roof tops--No tower needed. Not a good idea--Between the noise that the turbines impart to an occupied building, and possibly damaging the building/home by the turbine's vibrations--Free standing turbines (away from occupied areas/buildings/play fields/etc. is the better way to go.

If you can, I would highly suggest that you get kWH generation (numbers reported at least monthly, for a 1 year minimum period) of a successful installation before purchase.

Here is well respected wind information site:

http://www.wind-works.org/cms/index.php?id=17

The standard HAWT (horizontal axis wind turbine) is much more efficient--But does have its issues too.

Do it yourself Wind Turbines (HAWT type) are probably one of the projects that are better than typical off the shelf commercial units... Plus if you built it, you can repair it yourself too.

Regarding pumped hydro--That can be a very efficient and well respected way to generate/store electricity. However, smaller installations seem to be relatively rare (there are large utility scale dams/water pumped water storage systems out there).

Have you done the math on the reservoir designs/capacity/head to figure out if you can store enough water to make it practical for your needs?

I have read about one larger pumped hydro system using man made ponds in a hilly region--But (I don't remember why), did not seem too successful.

Here is one I found--Artificial upper pond, ocean was the "lower pond". Not economically viable:

https://en.wikipedia.org/wiki/Okinawa_Yanbaru_Seawater_Pumped_Storage_Power_Station

-BillNear San Francisco California: 3.5kWatt Grid Tied Solar power system+small backup genset

Categories

- All Categories

- 234 Forum & Website

- 142 Solar Forum News and Announcements

- 1.4K Solar News, Reviews, & Product Announcements

- 200 Solar Information links & sources, event announcements

- 901 Solar Product Reviews & Opinions

- 256 Solar Skeptics, Hype, & Scams Corner

- 22.5K Solar Electric Power, Wind Power & Balance of System

- 3.5K General Solar Power Topics

- 6.7K Solar Beginners Corner

- 1K PV Installers Forum - NEC, Wiring, Installation

- 2.1K Advanced Solar Electric Technical Forum

- 5.6K Off Grid Solar & Battery Systems

- 430 Caravan, Recreational Vehicle, and Marine Power Systems

- 1.1K Grid Tie and Grid Interactive Systems

- 656 Solar Water Pumping

- 817 Wind Power Generation

- 624 Energy Use & Conservation

- 624 Discussion Forums/Café

- 316 In the Weeds--Member's Choice

- 75 Construction

- 125 New Battery Technologies

- 108 Old Battery Tech Discussions

- 3.8K Solar News - Automatic Feed

- 3.8K Solar Energy News RSS Feed